Control of Asphalt Mixtures

SCOPE

This IM describes the Quality Control/Quality Assurance (QC/QA) procedures for monitoring and controlling plant-produced asphalt concrete mixtures on Quality Management of Asphalt (QMA) projects. Because the plant-produced mixtures may not develop test characteristics that meet design criteria, each mixture shall be evaluated during plant production. The evaluation procedures outlined herein are to be carefully followed so that all mix characteristics will conform to the appropriate requirements.

REFERENCE DOCUMENTS

Standard Specification 2303 Hot Mix Asphalt

AASHTO R 9-90 Acceptance Sampling Plans for Highway Construction

IM 204 Inspection of Construction Project Sampling & Testing

IM 208 Materials Laboratory Qualification Program

IM 216 Guidelines for Validating Test Results

IM 301 Aggregate Sampling & Minimum Size of Samples for Sieve Analysis

IM 302 Sieve Analysis of Aggregates

IM 320 Method of Sampling Compacted Asphalt Mixtures

IM 321 Method of Test for Compacted Density of Hot Mix Asphalt (HMA)(Displacement)

IM 322 Sampling Uncompacted Hot Mix Asphalt

IM 323 Method of Sampling Asphaltic Materials

IM 325 Compacting Asphalt Concrete by the Marshall Method

IM 325G Method of Test for Determining the Density of Hot Mix Asphalt (HMA) Using the Superpave Gyratory Compactor (SGC)

IM 336 Reducing Aggregate Field Samples to Test Samples

IM 337 Method to Determine Thickness of Completed Courses of Base, Subbase & Hot Mix Asphalt

IM 338 Method of Test to Determine Asphalt Binder Content & Gradation of Hot Mix Asphalt (HMA) by the Ignition Method

IM 350 Method of Test for Determining the Maximum Specific Gravity of Hot Mix Asphalt (HMA) Mixtures

IM 357 Hot Mix Asphalt (HMA) Mix Sample for Test Specimens

IM 510 Method of Design of Hot Mix Asphalt Mixes

RESPONSIBILITIES

Appendix A contains an outline of the responsibilities required for all parties.

The Table of Responsibility, in Appendix A, is broken up into two main categories, Quality Action and Type of Project. The Type of Project is further broken down into two sub-categories, Certified Plant Inspection (CPI) and QMA, and projects with small quantities. The Quality Action is subdivided into the types of work needing to be performed. These areas are General, Asphalt Binder, Aggregate, Loose Hot Mix, Compacted Hot Mix and Revisions. The table is organized in a way to represent how the work would progress during a Hot Mix Asphalt paving operation.

Each Quality Action identifies the group responsible for ensuring the desired action is performed. The groups are the Contractor (CONTR), Resident Construction Office/Project Engineer (RCE), District Materials Office (DME), and the Central Materials Office (CTRL).

In accordance with IM 205, submit a Quality Control Plan to the Engineer prior to the preconstruction meeting. The plan shall include as a minimum items mentioned in Appendix D.

In addition, there are certain levels of certification required to perform specific activities. Depending on the Quality Action, an individual might be required to be a HMA Sampler, Level I HMA, Level II HMA, Level I AGG, or a Level II AGG Certified Technician.

SAMPLING & TESTING

Samples of the combined aggregate, asphalt binder, and plant-produced mixture are obtained in accordance with IM 204 and analyzed as soon as the operations of the plant stabilize.

Only the information obtained from random samples as directed and witnessed by the Engineer and validated by comparison to one or more of the paired samples tested by the Contracting Authority will be used for specification. Additional samples of aggregate and uncompacted asphalt mixture may be taken to provide better quality control. The results of testing done on additional samples will be for informational purposes only. Any proposed changes in the quality control and verification sampling/testing frequencies require the approval of the District Materials Engineer (DME).

All testing done by the Contractor that is used as part of the acceptance decision shall be performed in qualified labs by certified technicians. On all QMA projects, the Level I HMA-Certified Technician is responsible for making sure that all samples are obtained according to the applicable IMs. Samples of uncompacted asphalt mixture and asphalt binder must be taken by someone with a minimum of a HMA Sampler Certification. Gyratory compactors not utilized in the independent assurance testing (IM 208 Appendix C) will not be allowed on QMA projects without permission from the DME.

Retain samples taken for acceptance purposes until the lot has been accepted.

A. Asphalt Binder

Sample the asphalt binder in accordance with IM 323 at the frequency defined in IM 204. AASHTO procedures are used in the testing of asphalt binder.

B. Aggregate

1. Sample the aggregate randomly in accordance with IM 301 at the frequency defined in IM 204.

2. Test the aggregate in accordance with IM 336 and IM 302.

3. When results from one or more sieves of the specified gradation sample are outside the allowable gradation tolerances, the Engineer may direct and witness one additional aggregate sample or process one loose asphalt mixture sample to include in the gradation acceptance decision.

C. Uncompacted Asphalt Mixture

1. Sampling

a. The specific ton or truckload to begin sampling will be determined by the Engineer using a random number system. Obtain production samples as directed and witnessed by the Engineer.

b. Sample the uncompacted asphalt mixture in accordance with IM 322 at the frequency defined in Article 2303.03, D, 3, B, 3, ii (or higher frequency pre-approved by the Engineer) quality control. Sample at the frequency defined in IM 204 for quality assurance.

2. Testing

a. Test the uncompacted asphalt mixture in accordance with IM 357, IM 350, IM 325G, and IM 338. When production of a bid item is expected to exceed three production days (small quantities excluded) and conditions/resources reasonably allow, test samples immediately “hot-to-hot” (without allowing the sample to cool) for at least one day at the beginning of production to aid in any future investigation of non-correlation that may arise throughout production.

b. Compact two Gyratory specimens to the number of gyrations specified in the contract documents. The laboratory Gmb of each production sample will be determined by averaging the Gmb results of the compacted specimens.

c. Laboratory voids, Pa, for each production sample will be determined from the results of laboratory Gmb and the corresponding individual Rice, Gmm, results.

d. Calibrate the Rice pycnometer at the beginning of a project and anytime that a correlation problem occurs.

3. Lot Size Determination

For PWL analysis of laboratory voids, lot size is defined as follows:

a. No less than 8 and no more than 20 sequential tests will constitute a lot (exceptions stated below).

b. After the 8th test, all subsequent samples collected over the remainder of that week will also be included in the lot up to a maximum of 20.

c. Once a lot has been established with at least 8 tests, a new lot will begin at the start of the following week or the day following the 20th sample, whichever occurs first. Lots shall not contain partial days. When the 20th sample is reached, include all samples taken that day in the lot.

d. When determining PWL lot size for lab voids, Sunday through Saturday defines a week.

e. If the bid item’s production has ended and fewer than 8 tests are available, those tests may be combined with the previous lot provided the maximum lot size has not already been reached. When combining results, if the day to be combined contains the 20th sample, include all samples for that day. Do not combine partial day’s results.

f. If samples cannot be combined with the previous lot due to maximum lot size restrictions or if fewer than 8 tests are available for the entire production of a bid item, combine those tests into a single lot and use the AAD analysis in IM 501.

g. Test strips will be considered a separate lot.

h. Use Table 2303.03-4 Uncompacted Mixture Sublot Size for determining sublots unless otherwise approved by the Engineer.

D. Compacted Asphalt Mixture

1. Sampling

a. For Class I compaction areas, sample the compacted asphalt mixture in accordance with IM 320 at the frequency identified in IM 204 Appendix F (or higher frequency pre-approved by the Engineer). See Article 2303.03, D, 4, a for alternate frequencies.

b. The Engineer will determine core locations randomly per Article 2303.03, D, 4, a. Randomly select the location within the length and width of each sublot. For PWL field voids lots, the width subjected to the random sampling shall coincide with the width eligible for PWL incentive/disincentive. This width shall be the nominal width of the travelled lane unless otherwise determined by the Engineer. Take samples from no less than 1 foot (300 mm) from the unconfined edge of a given pass of the placing equipment, except when the width of a single pass of the paver exceeds the width eligible for random sampling by more than 1 foot (i.e. For a 14-foot paving width on a 12-foot wide lane, a core location could randomly fall exactly 12 feet from centerline, assuming a two lane roadway. The outside 2 feet would then be deducted from the field voids lot quantity).

c. The Engineer will provide inspection staff to direct and witness the sampling and perform Gmb measurement during a time agreed between the Engineer and the Contractor. The Engineer should make every effort to meet the Contractor’s schedule.

d. The Engineer will transport the cores in accordance with IM 320, or secure the cores for transport by the contractor. The Engineer and Contractor will determine that cores are not damaged. The Engineer will decide if a core is damaged prior to testing.

2. Testing

a. Test the compacted asphalt mixture in accordance with IM 321 and IM 337.

b. Field voids will be determined using the average field Gmb result compared to the average maximum theoretical specific gravity, Gmm, obtained from samples, which correspond to the pavement from which the cores were taken.

c. PWL will be calculated using the method described in IM 501. The upper and lower specification limits for field voids are 3.5% and 8.5% respectively unless otherwise specified in the contract documents. If the PWL results in less than 100% payment, the calculations to identify outliers will be performed. If the calculations identify an outlier with a Quality Index (QI) of at least 1.80, the outlier will be eliminated and a new PWL calculated with the remaining cores. The new PWL will be used to determine payment unless it results in a greater penalty. The Quality Index is based on AASHTO R 9-90. Examples on how to calculate PWL, QI and outliers are located in IM 501.

d. Results must be determined and reported within the period of time specified.

3. Lot Size Determination

A lot shall be considered as one layer of one mixture bid item placed during a day’s production.

E. LONGITUDINAL JOINT COMPACTION

Refer to the applicable supplemental specifications.

VALIDATION

A. Defined

Validation is defined as the ability of two labs to achieve similar (statistically equivalent) test values on split or paired samples (split for aggregate samples and paired for asphalt concrete samples).

B. Aggregate Gradation Correction Factor

When comparing the cold-feed gradation to the ignition oven extracted gradation, a correction factor to adjust the extracted gradation must be determined in accordance with IM 501. Validation of the cold-feed gradation will be determined by comparing the cold-feed gradation and the corrected extracted gradation as shown on the comparison report for Cold-Feed & Ignition Oven in IM 216 Appendix A. The correction factors will be established by comparing an Agency cold-feed sample to an Agency ignition oven extracted sample. The Engineer may witness and secure a split cold-feed sample for validation in lieu of an ignition oven sample, in which case a correction factor is not needed.

C. Validation Requirements

1. When any of the following events occur, validation has not been achieved or maintained:

a. The difference between test results on each of two consecutive split/paired samples exceeds the IM 216 tolerance.

b. The difference between test results on any two of three consecutive split/paired samples exceeds the IM 216 tolerance.

2. Consecutive samples may be either validation samples tested sequentially with another lab or mix specific samples when other mixes are being tested for validation between the two labs. It may be necessary to examine validation of test results on consecutive samples of the same mix if more than one mix is being tested between the two labs. Validation problems sometimes only occur during testing of specific mix samples.

3. When validation for a particular test has not been achieved, all results for that day are considered invalid for that test.

4. To achieve or reestablish validation, a minimum of two consecutive test results must meet IM 216 tolerances.

5. When noncomplying material has been removed, the test results corresponding with the material will remain in the validation decision.

DISPUTE RESOLUTION

A. Investigation

When validation is not achieved or maintained, the DME will act as appropriate to resolve split/paired test result differences by choosing among the strategies below. The DME shall report the results of the investigation to the Contractor upon its conclusion. The DME may consider results from the Independent Assurance Program in the investigation. When non-validation of test results cannot be explained by an assignable cause as determined by the DME, the Engineer’s results will be used for acceptance.

1. Retest the same sample

2. The District labs will test additional verification samples.

3. The DME will review the sampling and testing procedures of both labs

4. The DME will immediately test samples sent in by the Contractor without allowing cool down and reheating (hot-to-hot testing).

5. Both labs will test samples using comparable reheat periods.

6. The DME will establish a correction factor based on the reheat evaluation outlined in Appendix B.

7. Both labs will test a sample that was taken and split by the Engineer.

8. Both labs and a third laboratory designated by the Contracting Authority will test a sample split three ways. The 3rd lab for state projects will normally be the Central Materials Lab.

9. The DME will establish a correction factor for the Contractor’s gyratory compactor based on the procedure described in Appendix C. The correction factor for Gmb should not exceed 0.030.

10. Verify both labs are compacting to the number of gyrations specified in the contract documents.

B. Quality Assurance Protocol

1. Resolution decisions by the Iowa DOT Central Materials Laboratory will be final.

2. During the period of production when validation cannot be achieved, the Engineer’s test results will be used for acceptance of the lot. The use of the Engineer’s test values for acceptance will be retroactive to the time when the first sample exceeded the validation tolerance. Similarly, when validation is regained, the use of the Contractor’s test results for acceptance is retroactive to the first test used to reestablish validation.

a. Over the period which validation cannot be achieved for aggregate gradation, the Engineer’s test results will be used for the entire gradation and applied to any calculations involving the gradation for the entire lot.

b. If validation cannot be achieved between the ignition oven extracted gradation and the Contractor’s cold-feed gradation, the Agency will run cold-feed gradations for validation in place of the ignition oven.

c. Over the period which validation cannot be achieved on

uncompacted asphalt mixture tests for Gmm or Gmb, the

Engineer’s test results will be used as follows:

i. For lots under the PWL acceptance plan,

a) The Engineer’s results and any other valid contractor’s results for the lot will be used in the calculations for average field voids and average lab voids.

b) If an F-test shows the variance of the Contractor’s results for the lot is significantly different (α=0.05) than that of the Engineer’s results, and the Engineer’s sample size is greater than 3, the Engineer’s results will replace all results used in standard deviation calculations for the lot. If not, the Contractor’s results will be used in standard deviation calculations for lab voids regardless of whether or not validation is achieved.

ii. For all other lots, the Engineer’s results will be used for any calculations involving that particular test value.

iii. Use a maximum lot pay factor of 1.000 for lab voids and field voids when the Engineer’s results are used for any portion of the lot.

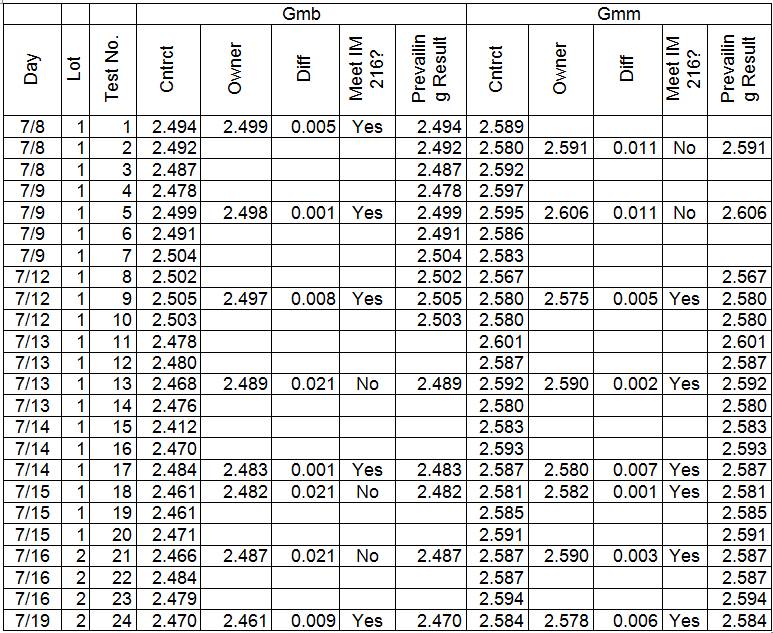

3. The following tables illustrate an example for implementing the dispute resolution QA protocol. In this example, the Contractor’s Gmb is invalid on 7/13, 7/15, and 7/16. The Contractor’s Gmm is invalid on 7/8 and 7/9. Therefore the Engineer’s results are used effective on the first day of noncompliance until part 5, C of this IM is satisfied.

The air voids are then calculated using the valid results. For days where the Contractor’s Gmm was valid, but the Gmb was not, the air voids were calculated for each test using the Engineer’s Gmb for that day and Contractor Gmm for that test. The same applies when Gmb is valid and Gmm is not. Voids are also calculated using just Contractor results and just the Engineer’s results for further analysis of variability.

|

Lab Voids |

|||||

|

Day |

Lot |

Test No. |

Validated Results |

Contractor |

Owner |

|

7/8 |

1 |

1 |

3.7 |

3.7 |

3.6 |

|

7/8 |

1 |

2 |

3.8 |

3.4 |

|

|

7/8 |

1 |

3 |

4.0 |

4.1 |

|

|

7/9 |

1 |

4 |

4.9 |

4.6 |

|

|

7/9 |

1 |

5 |

4.1 |

3.7 |

4.1 |

|

7/9 |

1 |

6 |

4.4 |

3.7 |

|

|

7/9 |

1 |

7 |

3.9 |

3.1 |

|

|

7/12 |

1 |

8 |

2.5 |

2.5 |

|

|

7/12 |

1 |

9 |

2.9 |

2.9 |

3.0 |

|

7/12 |

1 |

10 |

3.0 |

3.0 |

|

|

7/13 |

1 |

11 |

4.3 |

4.7 |

|

|

7/13 |

1 |

12 |

3.8 |

4.1 |

|

|

7/13 |

1 |

13 |

4.0 |

4.8 |

3.9 |

|

7/13 |

1 |

14 |

3.5 |

4.0 |

|

|

7/14 |

1 |

15 |

3.9 |

6.6 |

|

|

7/14 |

1 |

16 |

4.2 |

4.7 |

|

|

7/14 |

1 |

17 |

4.0 |

4.0 |

3.8 |

|

7/15 |

1 |

18 |

3.8 |

4.6 |

3.9 |

|

7/15 |

1 |

19 |

4.0 |

4.8 |

|

|

7/15 |

1 |

20 |

4.2 |

4.6 |

|

|

7/16 |

2 |

21 |

3.9 |

4.7 |

4.0 |

|

7/16 |

2 |

22 |

3.9 |

4.0 |

|

|

7/16 |

2 |

23 |

4.1 |

4.4 |

|

|

7/19 |

2 |

24 |

4.4 |

4.4 |

4.5 |

Because the owner has more than 3 test results, an F-test determines which standard deviation to use (Contractor’s or Engineer’s) in the PWL calculation. Since the F-test p-value is greater than 0.05, the variances are not considered significantly different and the Contractor’s standard deviation is used. F-test is calculated in excel as “=FTEST(Contractor’s air voids range, Owner’s air voids range).

|

Lot 1 Stdev (contractor) |

0.922 |

|

Lot 1 Stdev (owner) |

0.385 |

|

Lot 1 F-test (p-value) |

0.06 |

The validated results are used to calculate the average field voids as shown:

|

Avg |

3.8 |

|

Stdev |

0.922 |

|

Qil |

0.916 |

|

Qiu |

1.252 |

|

PWL |

71.7 |

The PWL for Lot 1 is 71.7. Because the Engineer’s results were used to calculate the average (and/or standard deviation) for lab voids, the maximum pay factor is 1.00. The Gmm used for Field Void calculations also only considers valid results for the lot. The average Gmm for valid results is 2.587 for Lot 1.

This example also illustrates when to begin a new lot. The first lot began on Thursday, 7/9/09. Since only 7 tests were run that week (Sun-Sat defines week), the lot carries over to the following week. The 8th test was run on 7/12/09 (Sunday), so the lot includes all tests for the remainder of that week until either the 20th test is reached or Saturday 7/18/09 is reached, whichever comes first. The 20th test was reached on 7/15/09 so the next lot begins on the first test of the following working day (7/16/09). Had more tests been run on 7/15/09 all tests that day would have been included in the lot even though the total lot size would exceed 20. Lots are not divided in the middle of a working day.

PRODUCTION TOLERANCES

Production tolerances are listed in the specifications.

Investigate variations between two consecutive test results in Gmb or Gmm of more than 0.030 promptly since these tests reflect significant changes in binder content, aggregate properties and/or gradation. In some cases variations may be attributed to segregation, thoroughness of mixing, sampling procedure, and changes in aggregate production.

If the test results in a series of split/paired samples (minimum of 3 samples) are not variable and random (results are consistently higher or results are consistently lower) and the difference between each split/paired test result is greater than half of the IM 216 tolerance, the DME may establish a correction factor for the Contractor’s gyratory compactor based on the procedure described in Appendix C. The correction factor for Gmb should not exceed 0.030.

REPORTING

For each production sample of loose asphalt mixture the Contractor will determine, report, and plot Gmb, Gmm and Pa. Binder content measurement by an approved method will be determined, reported, and plotted daily. Gradation will be determined, reported and plotted daily. Make the inter lab correlation reports available.

Test results are to be recorded and plotted in the computer programs provided by the Iowa DOT (http://www.iowadot.gov/Construction_Materials/hma.html). The computer programs act as a tool for documenting project data and applying the specification. The specification and IMs will always govern when errors are encountered in the software. Microsoft Excel 2007 (or newer) is required (or equivalent spreadsheet software capable of reading and writing *.xlsm and *.xlsx file types). The recommended minimum system requirements include a 2.3 Ghz processor or higher with at least 2 GB of physical memory and a wireless network adapter with internet access. Copies of the electronic spreadsheet file containing the completed Daily HMA Plant Report (Form #800241) shall be provided to the DME and the Engineer within 4 hours of beginning operations on the next working day. The Engineer may extend this time on days when longitudinal joint cores are sampled and tested. Alternatively in these cases, the Engineer may accept partially completed reports until results are available. Use electronic mail (or DocExpress®) as the method of delivery unless otherwise approved by the Engineer. Copies of computer files containing the project information shall be furnished to the Engineer on a CD or portable memory device upon project completion. An additional copy of the files shall be furnished to the DME on a CD or portable memory device.

ADJUSTING (TROUBLESHOOTING)

As stated in Article 2303.01, “The Contractor shall be responsible for all aspects of the project, provide Quality Control management and testing, and maintain the quality characteristics specified”.

The Contractor is responsible for making changes, as necessary, to achieve target values specified on the JMF. These changes can include adjusting the proportions of aggregate and asphalt binder necessary to meet the JMF. If a change in the target gradation is desired, obtain approval of a new JMF from the DME. Changes in the target gradation cannot be set outside of the control points. The Contractor may change the target binder content to maintain the required mixture characteristics, provided the appropriate documentation and reporting is performed. The Contractor may change binder sources provided the Engineer receives written notification (or e-mail) prior to the substitution. Report all changes in proportions on the Daily HMA Plant Report (Form #800241).

The addition of new materials to the JMF may be approved by the Engineer without evaluating mix volumetrics in the laboratory if the materials are produced from geologically comparable sources, do not constitute more than 15 % of the total aggregate, meet quality requirements, and produce mixes that meet design criteria. When aggregates are introduced from sources that are not geologically comparable or otherwise differ significantly, complete laboratory mix design testing and approval is required.

A polymer modified binder may be substituted into the JMF provided the original PG grade and temperature spread is met or exceeded. In this case, verify the JMF target air voids are met at the design binder content. If the substitution results in a Gmb change of more than 0.02, or more than 0.2% deviation from the target air void content, then complete laboratory mix design testing and approval is required. If the original JMF required moisture susceptibility testing and has consistently demonstrated acceptable SIP values in the field, the original anti-strip agent (if needed) and dosage rate may be used in lieu of IM 319 re-evaluation. Plant produced mix will still be tested for moisture susceptibility.

When a stockpile of recycled asphalt materials (RAM) constitutes less than 15% of the JMF, it may be substituted by another source of equivalent classification and quality (Certified, Classified, Unclassified) to finish the project. In this case, update the JMF by entering the new RAM binder content, specific gravity, gradation, and absorption into SHADES. Verify the volumetrics remain compliant with the specifications by testing a lab compacted sample.

Moving averages and the gyratory compaction slope assist in identifying potential problems before they arise. Watch the trends in the moving averages (approaching a specification limit) and the slope of the compaction curve. The slope of the compaction curve of plant-produced material shall be monitored and variations in excess of ± 0.40 of the mixture design gyratory compaction curve slope may indicate potential problems with uniformity of the mixture.

GUIDANCE TABLES

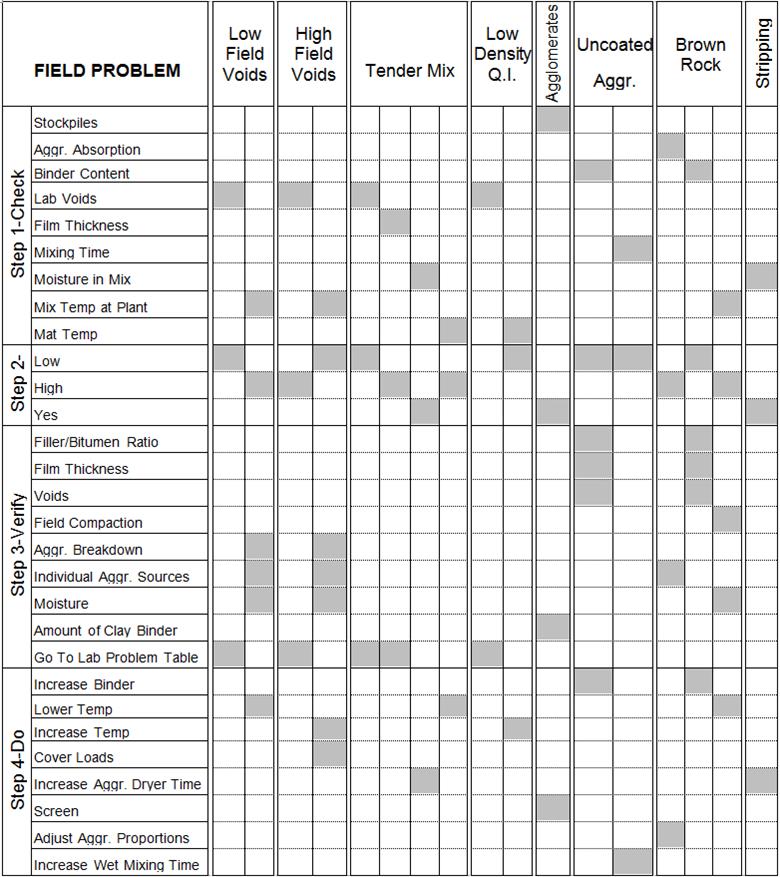

The tables below are intended to provide guidance on dealing with the most common problems, which arise during the production of asphalt concrete mixture. The first table deals with problems, which can show up in the laboratory setting and the second table deals with problems, which can appear in the field.

The following example explains how to read the tables. Both tables are read downward. The shaded regions are the items to be considered for adjusting purposes.

Lab Problem Table

The first step is to identify which lab problem is occurring. If “Low Voids” is the identified problem, move down the column to the “Step 1 Check”. Assuming the first check is to be made on the “Binder Content”, move down the column to “Step 2 If”. If the Binder Content is high proceed to “Step 3 Verify”. Each of the shaded items identified in the “Step 3 Verify” should be looked at before proceeding further. Assuming that the items in “Step 3 Verify” are on target, go to “Step 4 Do”. In this case, the action to be taken in “Step 4 Do” is to “Lower Binder” in the mix. In all cases, the items in the “Step 3 Verify” are assumed to be within the allowable tolerances and won’t fall outside of allowable tolerances if the action in “Step 4 Do” is taken.

Field Problem Table

The first step is to identify which field problem is occurring. If “High Field Voids” is the identified problem, move down the column to the “Step 1 Check”. Assuming the first check is to be made on the “Lab Voids”, move down the column to “Step 2 If”. If the Lab Voids are high proceed to “Step 3 Verify”. Each of the shaded items identified in the “Step 3 Verify” should be looked at before proceeding further. Assuming that the items in “Step 3 Verify” are on target, go to “Step 4 Do”. In this case the process of looking at the “Step 3 Verify” would lead to the Lab Problem Table and cause one of the actions for High Lab Voids to be used.

In all cases, the items in the “Step 3 Verify” are assumed to be within allowable tolerances and won’t fall outside of allowable tolerances if the action in “Step 4 Do” is taken.