INSTRUCTIONS FOR COMPLETION OF

The new reporting process does not include Mobile Mixer information. Use the following forms and reports when using a Mobile Mixer:

Form M or E 115 Air & Slump Record

Form M or E 120 Mobile Mixer Data Record

Report #820180 Gradation Test

Report #821297 Nuclear Density of Plastic PC Concrete

Report #820020 Mobile Mixer Calibration

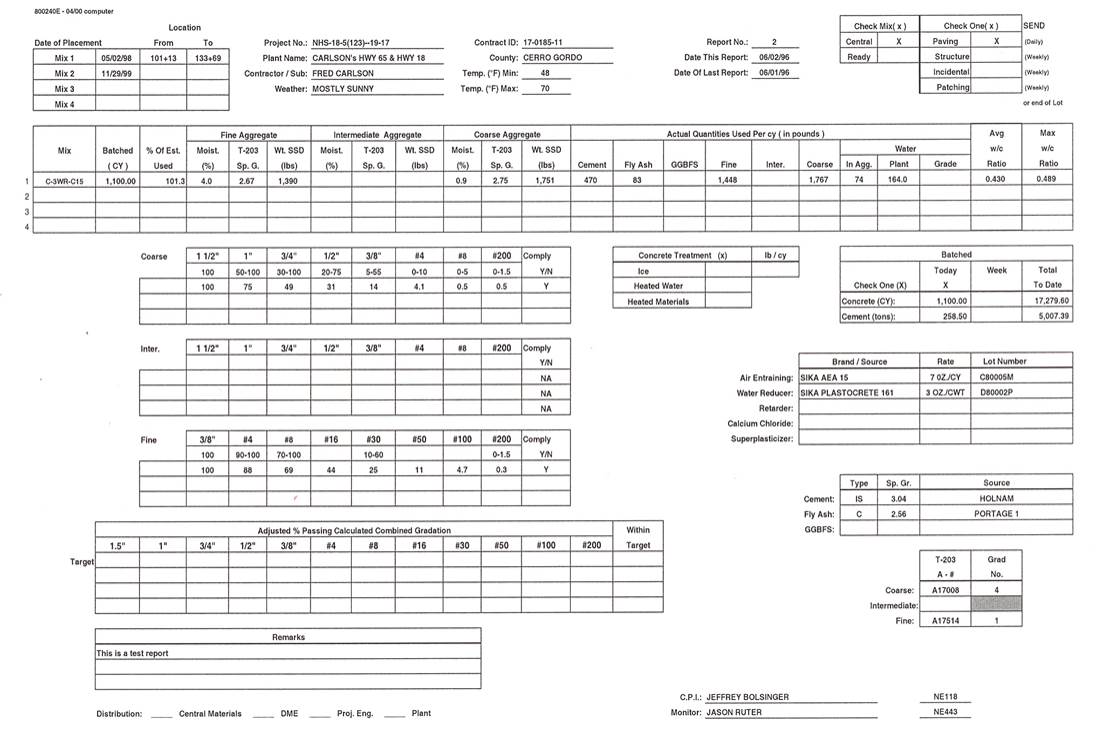

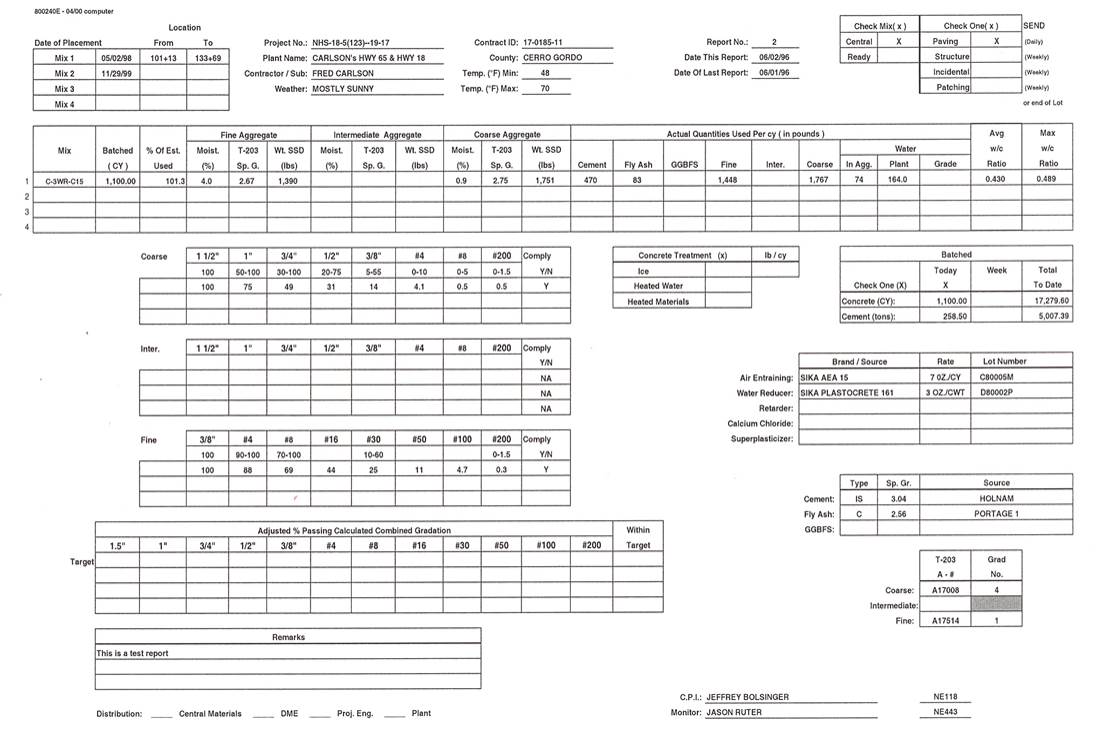

Project No.

Enter the project number listed on the plans.

Enter the name of the ready mix plant and location for structural concrete. Enter the approximate location of a paving plant set up by a contractor.

Example: Croell - Waverly (Ready Mix)

2 miles NW of Waverly (Paving Plant)

A group of people or a company must perform the work being done, either a prime or sub contractor. Enter the name of the contractor performing the work. If it is a subcontractor, list this after the contractor name.

Enter a brief description of the actual weather conditions at the paving plant. Weather conditions are not required for structural concrete (Ready Mix).

Enter the nine-digit contract number listed at the top of a contract. This is not the five-digit accounting ID number listed with the project number.

Enter the county listed on the project plans.

Temperatures, Min. & Max.

An air temperature shall be recorded early in the morning for the minimum and around mid-afternoon for the maximum. Take the temperatures in a shaded area, otherwise they are meaningless. Temperatures are not required for structural concrete (Ready Mix).

Report No.

Start with the number 1 at the beginning of work for each project. The ending report number shall coincide with the last day each item is completed for paving and the last week for structural. Do not restart the report sequence if the project carries over to the next year.

Example: (Paving) 16 days of 200-mm slip form paving - report 1 through 16.

(Ready Mix) 8 weeks of concrete on Des. 1290 - report 1 through 8.

Enter the date the concrete is placed for each day of paving. Enter the last day of the workweek for structures (normally the Saturday date).

Self-explanatory.

Design No.

Enter the design number of the structure where the concrete is being placed on each project. Leave this space blank on paving projects.

Check Mix (Central or Ready)

Place an “X” in the appropriate box provided indicating how the concrete is being produced.

Check Usage (Paving, Structural, Incidental, Patching)

Place an “X” in the appropriate box provided to indicate the type of work where the concrete is used.

Date (Mo./Day)

This column is only used for Ready Mix concrete applications. Enter the month and the date for each day of production during the week.

Example: 5/24, 7/01, 12/03, etc.

Enter the mix number being used that is listed in the proportion tables of IM 529.

Location- Station (Beg./End/Dir)

Enter the beginning and ending station for concrete placed daily by mix. Enter the direction (N, S, E, W) for divided sections or B for 2-lane sections. For structural concrete enter the unit placed (Example: pier, cap, footing, deck). Enter item placed for other work. (Example: sidewalk, drive) The grade inspector will provide the location or item placed to the plant inspector.

Enter the total cu. yds. (m3) batched for each mix for a paving plant. Enter the total cu. yds. (m3) batched for each unit poured for structures.

% Of Est. Used

Enter the percent of estimated concrete used. The grade inspector will provide the % of estimate used ((cubic yards used / cubic yards estimated) X100) to the plant inspector

Fine, Intermediate & Coarse Aggregate (Moisture)

Enter the percent moisture once in the morning and once in the afternoon for paving projects. Enter the percent moisture for each unit poured on structures.

Fine, Intermediate & Coarse Aggregate (T203 sp gr)

Enter the specific gravity for each aggregate listed in the T203 source tables.

Fine, Intermediate & Coarse Aggregate (Dry Mass or Wt.)

Enter the weight (mass) of each aggregate calculated by absolute volumes.

Actual Quantities Used Per cu. yds. (m3) in Kilograms (Pounds)

Cement Enter the pounds (kilograms) of cement calculated by absolute volumes.

Fly Ash Enter the pounds (kilograms) of fly ash calculated by absolute volumes.

GGBFS Enter the pounds (kilograms) of ggbfs calculated by absolute volumes.

Fine Enter the actual pounds (kilograms) of fine aggregate adjusted by moisture content.

Inter. Enter the actual pounds (kilograms) of intermediate aggregate adjusted by moisture content.

Coarse Enter the actual pounds (kilograms) of coarse aggregate adjusted by moisture content.

In Agg. Enter the calculated difference between the actual weights (masses) and the dry weights (masses) of both fine and coarse aggregates.

Plant Enter the average pounds (kilograms) of water added at the plant for each cu. yd. (m3).

Grade Enter the average pounds (kilograms) of water added on the grade (when permitted by specification).

Enter the ratio of total water, including water in the aggregates and water added on the grade, in one cu. yd. (m3) divided by the total sum of cement, fly ash, and ggbfs in one cu. yd. (m3), report to three decimal places.

This section of the report is for reporting the Certified Plant Inspector gradation test results for the coarse and fine aggregates being used in the mix. If one of the tests fail and backups are tested, record the average in the column provided, which is located just right of the specifications column.

Batched (Today or Week)

Place an “X” under the Today column if the report is being submitted daily (paving).

Place an “X” under the Week column if the report is being submitted weekly (structures).

Enter the total cu. yd. (m3) of concrete batched under the appropriate column. Paving plant totals are normally under the Today column; structural concrete totals are normally under the Week column.

Enter the running total for both concrete and cement.

Air Entraining (Air Ent.)

Enter the brand name or source, average rate per cu. yd. (m3), and lot number.

Water Reducer (Wat. Red.)

Enter the brand name or source, average dosage rate, and lot number.

Enter the brand name or source, average dosage rate, and lot number.

Calcium Chloride (Cal. Chlor.)

Enter the brand name or source, average dosage rate, and lot number only when added at the plant site.

Superplasticizer (Superplas.)

Enter the brand name or source, average dosage rate, and lot number.

Place an “X” directly behind Ice, Heated Water, or Heated Materials, if one or more are used. If ice is used to cool the mix, enter the pounds (kilograms) of ice per cu. yd. (m3).

Enter the cement type, specific gravity, and source. See IM 401 for the actual source name.

Enter the type and specific gravity and source. See IM 491.17 for the actual source name.

Example: Chillicothe and ISG Headwaters are not source names.

Ottumwa is the source name.

Enter the T203 A number, and gradation number.

Enter the grade, specific gravity, and source. See IM 491.14 for the actual source name.

Enter the T203 A number, and gradation number.

Enter the T203 A number.

Enter delays, which may take place. Enter description of noncomplying test results.

CPI

Enter the Certified Plant Inspector name and certification number.

Enter the plant monitor name and certification number.

If using the computer spreadsheet, most of this information will be entered on the Project Information and Mix Information sheets and automatically transferred to the Report. For QMC and BR mixes, the combined gradation will be calculated from aggregate percentages entered in the Mix Information Station From and To, Totals to Date Cement and Concrete, and Remarks will be entered directly on the Report.

The next page is an example of a completed Paving Plant Report.