of the neoprene compound and the grade of steel used for laminates.

MONITOR SAMPLING & TESTING

The amount of monitor sampling and testing will generally depend upon the amount of material supplied by each manufacturer and the time since the last sample was obtained.

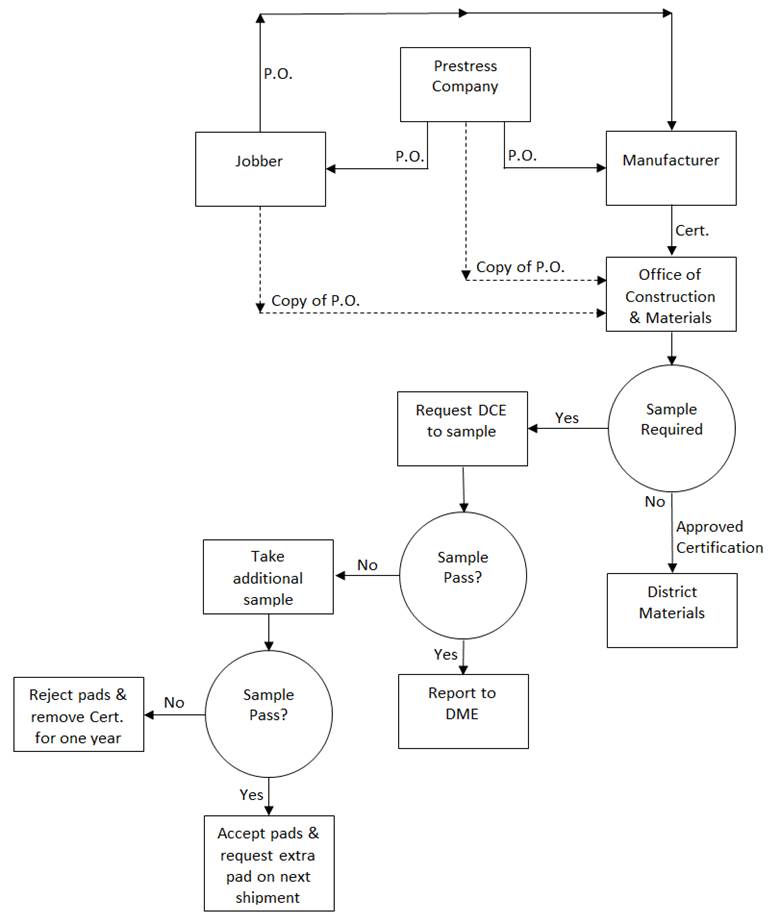

A. Sampling Laminated/Elastomeric Pads

When a laminated pad is to be tested, the Office of Materials shall notify the manufacturer to furnish one extra pad with shipment. If the pad conforms to the specification, the shipment will be approved. If the pad does not conform to the specification, an additional pad shall be tested. If the additional sample pad conforms to the specification, the prestress company must request an additional replacement pad from the manufacturer, and the shipment will be approved. If the additional sample does not conform to the specifications, the entire shipment of pads will be rejected and the manufacturer removed from the approved source list for a period of one year. (See flow diagram in Figure 1.)

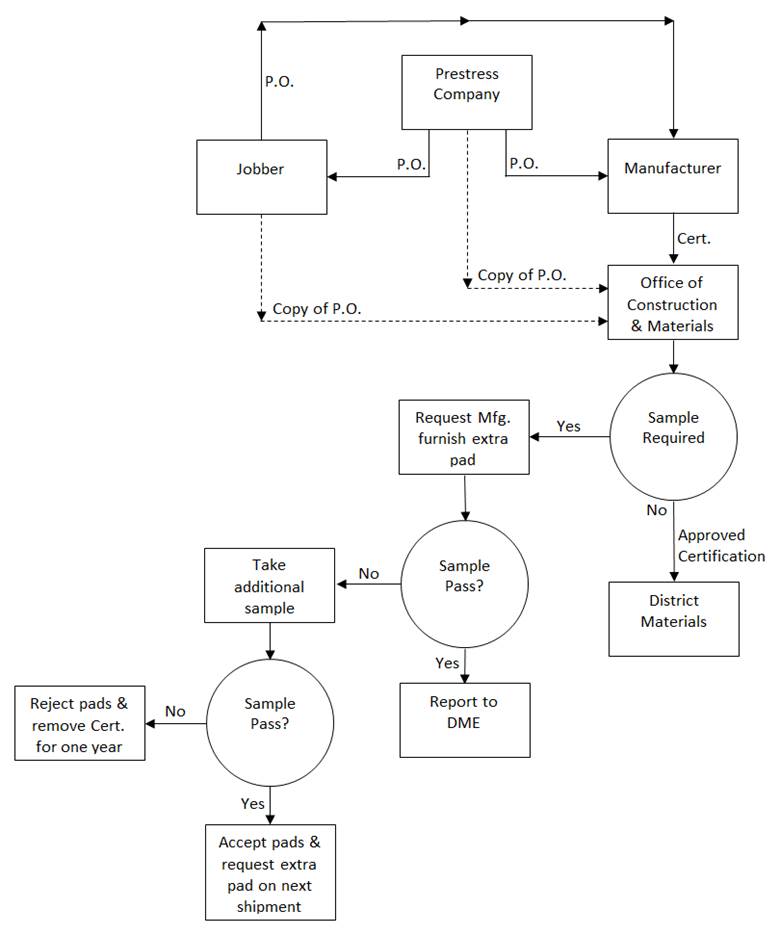

B. Sampling Homogeneous Pads

If a monitor sample is required for homogeneous (non-laminated) pads, an extra pad will not normally be shipped. The prestress company must request a replacement pad from the manufacturer. The same procedure concerning additional samples, etc. as with laminated pads will be followed. (See flow diagram in Figure 2.)

REPORTING

A copy of an approved certification in the case of shipments furnished by an approved manufacturer, or of the test results in case sampling is required, will be forwarded to the appropriate District Materials Engineer. Based on a certification or test results, approval of pads for a project will be reported by the District Materials Engineer’s Office.

APPROVED SOURCES

Currently approved sources for furnishing bridge bearing pads on the basis of certification are indicated in Appendix C.

FIGURE 1. - ACCEPTANCE PROCEDURE FOR LAMINATED

NEOPRENE BEARING PADS FROM APPROVED SOURCES

FIGURE 2. - ACCEPTANCE PROCEDURE FOR NON-LAMINATED

NEOPRENE BEARING PADS FROM APPROVED SOURCES