DETERMINING PRESENCE OF ANTI-STRIP

AGENT IN CUTBACK ASPHALT (RAPID FIELD TEST)

SCOPE

This IM is intended to provide the procedure for determining the presence of anti-strip agents in cutback asphalt. The test is sensitive to the amount of agent present, but will not determine the amount of anti-strip present.

APPARATUS & MATERIALS

· Glass bottle with screw top, 2 oz. (60 ml) capacity

· Seamless ointment tin, 6 oz. (180 ml) capacity

· Small spatula

· Paper towel

· Standard Ottawa sand, 20-30 mesh (850-600 μm), ASTM C190

· Potable water

· Diluents: unleaded gasoline, naphtha solvent, or mineral spirits

PROCEDURE

Sample Preparation

Cutback asphalt of a viscosity grade of 800 or higher must be thinned to an easy flowing consistency before testing. Viscosity grades of 250 or lower may be tested without dilution. Thin the heavier grades as follows:

CAUTION! Thick cutback asphalt must be heated in order to handle easily. The cutback must be cooled to less than 140°F (60°C) (touchable) before the diluent is added. This dilution operation should be performed where there is good ventilation and no open flames. Smoking should not be permitted in the vicinity.

1. Fill the 6 oz. (180 ml) ointment tin about 1/3 full with cutback asphalt to be tested.

2. Add diluent in small increments and mix into the cutback after each addition using the spatula. Continue adding diluent until the consistency is similar to that of thick cream.

About 1 tsp. (5 ml) of diluent is usually required for an MC-800 and 2 tsp. (10 ml) for an MC-3000. Slightly more than these amounts may be required to compensate for evaporation loss or a particularly thick cutback.

Test Procedure

1. Fill the 2 oz. (60 ml) bottle 1/2 full with standard Ottawa sand and add water heated to a temperature of about 100°F (38°C) to cover the sand surface to a depth of about 1/2 in. (12.5 mm). NOTE: Tap water adjusted to a lukewarm condition is adequate.

2. Add about 1 gram of the prepared cutback material by dripping it from the end of the spatula onto the water surface in the bottle.

NOTE: One gram of material is a quantity sufficient to form a pool about the size of a nickel coin when dripped onto a flat surface.

3. Cap the bottle with the screw top and shake vigorously for about 30 seconds. Then open the bottle and pour off the excess water.

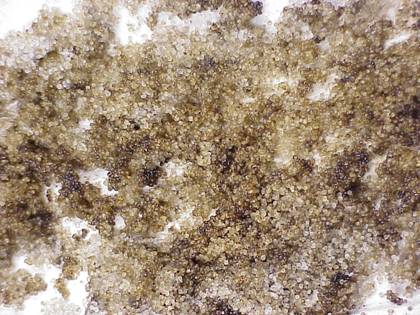

4. Gently tap the wet sand from the bottle onto a paper towel and spread to a thin layer for inspection.

DOCUMENTATION

1. Visually inspect the wet sand for the degree of uniformity of asphalt coating.

2. If the cutback contained an effective amount of anti-strip agent, the sand will be fully coated with asphalt to form a homogenous mix of uniform color. The results are then reported as positive.

NOTE: Sand that is partially coated to a uniform light brown color and contains small globules of excess asphalt is not considered a homogenous mix.

3. If the cutback is deficient in anti-strip agent, the sand and asphalt will not form a homogenous mix. The results are then reported as negative.

|

|

|||

|

Non-Homogenous Mix (Results Negative) |

|||

|

|

|||

|

Homogenous Mix (Results Positive) |