GENERAL

This IM is intended to provide details for trenchless steel pipe construction.

BASIS OF ACCEPTANCE

Acceptance for incorporation into a project shall be from an approved Steel Pipe Pile source prior to the letting and on the basis of a certified mill test analysis of the steel. Steel pipe shall meet the requirements of IM 107, Group 1, Buy America.

Approved Rolling Mills for Steel Pipe Piles are listed in IM 467.03 Appendix A

The manufacturer and/or contractor shall furnish an identification list for each and every shipment to a project. It shall include the project number, design number, heat number, number of pieces, size and length of pipe in the shipment. A Certified Mill Analysis for each shipment is required. The Mill Analysis shall itemize the materials, the ASTM steel designation, section number description, heat number, actual or theoretical mass and the physical as well as the chemical test analysis/characteristics. The Mill Analysis shall indicate compliance with the applicable specification requirements.

At the time of shipment one copy of properly identified Certified Mill Analysis and identification list (showing project number, county, size and length of pipe, and number of pieces) shall be forwarded to the Project Engineer and one copy to the respective District Materials Engineer.

CARRIER PIPE WELD PROCEDURE

|

|

|

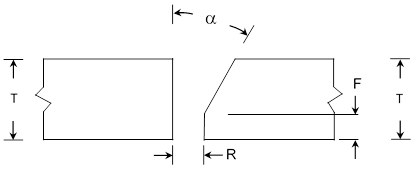

Thickness T ≥ 3/8” Root Opening R 0 to 3/16” Root Face F 0 to 1/8” Groove Angle a 30° to 45°

|

Welder Qualification in accordance with IM 560 except AWS D1.1 is allowed.

Welder Certification – Position of Groove 3G & 4G or 5G, AWS D1.1 or D1.5.

Preheat Temperature ≥ 32° F.

Welding process - Shielded Metal Arc Weld (SMAW) or Flux Core Arc Weld (FCAW).

Weld according to IM 558.

CARRIER PIPE WALL THICKNESS

|

Nominal Diameter (inches) |

Nominal Thickness (inches) |

|

12 ¾ and under |

0.188 |

|

14 |

0.250 |

|

16 |

0.281 |

|

18 |

0.312 |

|

20 and 22 |

0.344 |

|

24 |

0.375 |

|

26 |

0.406 |

|

28 |

0.438 |

|

30 |

0.469 |

|

32 |

0.500 |

|

34 and 36 |

0.531 |

|

38 |

0.562 |

|

40 |

0.594 |

|

42 |

0.625 |

|

44 and 46 |

0.656 |

|

48 |

0.688 |

|

50 |

0.719 |

|

52 |

0.750 |

|

54 |

0.781 |

|

56 and 58 |

0.812 |

|

60 |

0.844 |

|

62 |

0.875 |

|

64 |

0.906 |

|

66 and 68 |

0.938 |

|

70 |

0.969 |

|

72 |

1.000 |

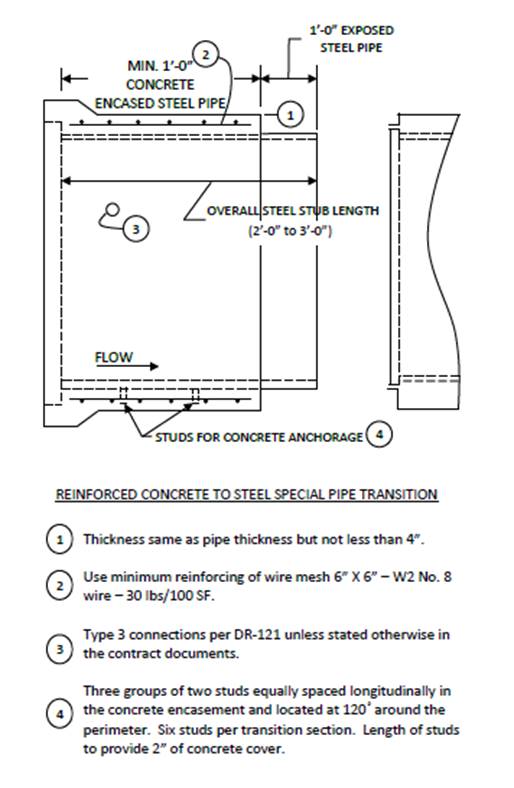

CARRIER PIPE CONCRETE TRANSITION END SECTION