|

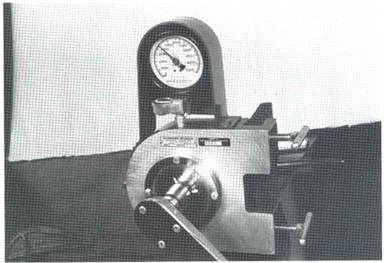

ROTATIONAL CAPACITY TEST |

|

|

Long Bolt Procedure |

|

|

|

|

|

Procedure is required by Article 2408.03, S, 4 and further described in Materials IM 453.06B. |

|

|

(Photos taken by Bill Burns, Iowa DOT.) |

|

|

|

|

|

REQUIRED MATERIAL: |

|

|

|

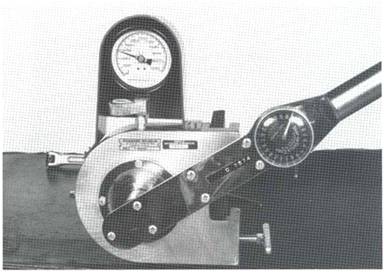

Calibrated Tension Measuring Device |

|

|

Torque Wrench and Spud Wrench |

|

|

Washers and/or Shims |

|

|

Fasteners from same R-C Lot number |

|

|

|

|

|

|

|

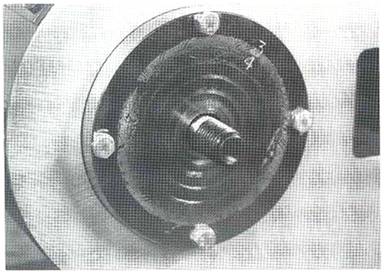

Step 1. |

Mark the 3rd through 5th full threads from the shank of the bolt. |

|

|

|

|

|

|

|

Step 2. |

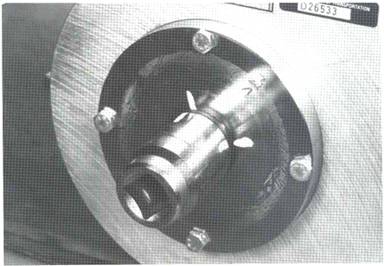

Install bolt into the Skidmore. |

|

|

|

|

|

|

|

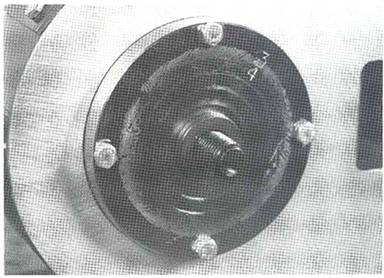

Step 3. |

Install the required number of washers and/or shims to just cover the 3rd, but not more than the 5th thread, as marked in Step 1. (Must have 1 washer under the nut.) |

|

|

|

|

|

|

|

Step 4. |

Tighten nut to Snug Tight. (IM 453.06B, Appendix A, Table A-1) |

|

|

|

|

|

|

|

Step 5. |

Match-mark the bolt tip, nut, and base plate. |

|

|

|

|

|

|

|

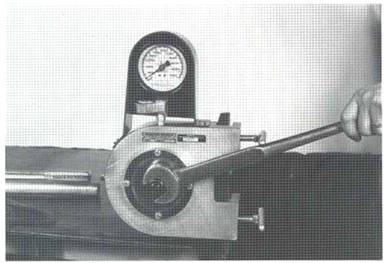

Step 6. |

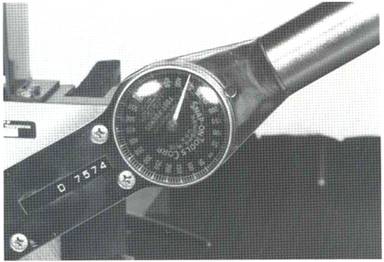

“Zero” torque wrench. |

|

|

|

|

|

|

|

Step 7. |

Tension bolt to at-least value given in IM 453.06B, Appendix A Table A-2. |

|

|

|

|

|

|

|

Step 8. |

Record torque tension from Step 7 on R-C Worksheet. |

|

|

|

|

|

|

|

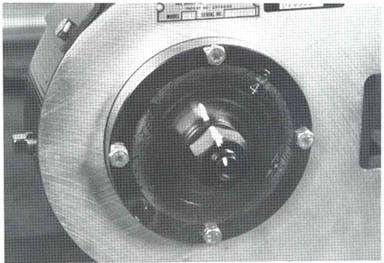

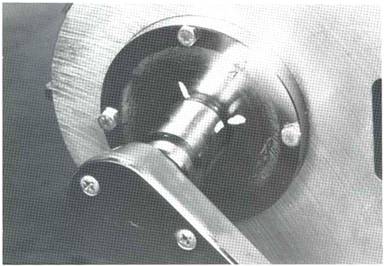

Step 9. |

Match-mark socket to base plate. (Use Turn-of-Nut rotation amount.) IM 453.06B, Appendix A, Table A-3 |

|

|

|

|

|

|

|

Step 10. |

Rotate nut the required Turn-of-Nut amount. (IM 453.06B, Appendix A, Table A-3.) |

|

|

|

|

|

|

|

Step 11. |

Record tension on R-C Worksheet. Must be equal to or greater than value in IM 453.06B, Appendix A, Table A-4. |