DETERMINING PAVEMENT RIDE QUALITY

SCOPE

This IM describes procedures used to perform smoothness testing on pavement and bridge surfaces. A certified person is required to perform the testing, evaluation, and reporting. An approved apparatus must be used to test and evaluate all surfaces.

PROCEDURE

1. Apparatus

a. Inertial Profiler meeting the requirements of AASHTO M328 (this requires an auto start/stop) and currently certified on the Iowa DOT test strips or other state test strips approved by the Iowa DOT. For all surfaces other than dense graded HMA, a large footprint laser is required.

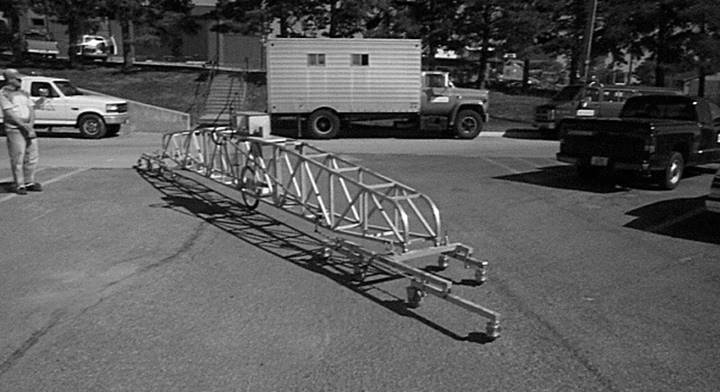

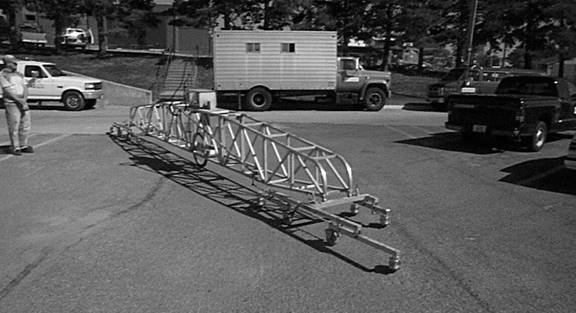

b. California or Ames Engineering type, 25-foot profilograph. See Figure 1 or Figure 2.

Figure 1 Ames Engineering profilograph

Figure 2 California profilograph

Note: a California or Ames Engineering type, 25-foot profilograph may only be used for internal information or for testing and evaluation under Section 2428, Smoothness of Bridge Decks and Bridge Deck Overlays.

c. Ten-foot straight edge or a 10-foot straight edge software simulation.

d. Distance measuring wheel or tape.

e. Latest version of ProVAL software. http://www.roadprofile.com/proval-software/current-version/

f. Latest version of the Iowa DOT Spreadsheet, Profile Summary Sheet and the current ProVAL template. https://iowadot.gov/construction_materials/Materials-forms

2. Profiler Approval-All profilers must be checked and approved by the Iowa DOT Materials Laboratory before each construction season for proper operation. Profilers checked and approved in another state in the current year may be approved. Submit a request to Special Investigations Engineer for consideration of approval.

a. Inertial Profilers

i.ProVAL will be used to analyze the inertial profiler files. The criterion for approval includes High pass and low pass filters set to 0. All other settings according to manufacturer’s recommendation (The settings used for approval will be the same used throughout the season).

ii.Submittal of 10 good runs of the test strip as ProVAL readable files.

iii.The DMI distance shall be within 0.15% of the actual test strip distance.

iv.The equipment repeatability score with the IRI filter shall be 0.90 or greater.

v.The equipment accuracy score with the IRI filter shall be 0.88 or greater when compared to the reference profiler.

vi.The average IRI shall be within 5% of the reference profiler IRI.

b. California or Ames Engineering type, 25-foot profilograph.

i. Contact the Special Investigations Engineer to arrange for verification of calibration with the Iowa DOT test equipment. The units shall be within 0.5 inches per mile on the 0.2-inch blanking band. Re-evaluation may be required if the unit fails to correlate with the Iowa DOT monitor testing.

ii. Only computer reductions will be allowed for official reports.

iii. Settings-Below are the settings that shall be used for testing in Iowa.

Table (1)-PROFILOGRAPH FACTORS / PROFILER CALIBRATION |

||||

|

|

|

Filter Settings |

Tire Pressure |

|

|

MANUFACTURER |

COMPUTER |

LOW PASS/ DATA |

170kPa (25 PSI) |

OTHER |

|

AMES or CA profilograph |

X |

2.0 |

X |

--- |

|

AMES LISA |

X |

2.0 |

--- |

10 PSI |

|

MCCRACKEN |

X |

2.0 |

X |

--- |

|

SSI |

X |

2.0 |

X |

--- |

|

HIGH SPEED PROFILER |

X |

2.0 |

--- |

As Calibrated |

|

Table (2)-PROFILOGRAPH/ PROFILER REDUCTION SETTINGS |

|

|

Blanking Band* |

0.20 inches |

|

Scallop Rounding |

0.01 inches |

|

Minimum Scallop Height |

0.03 inches |

|

Minimum Scallop Width |

0.08 inches on trace (2.0 ft. actual distance) |

|

Filter Type |

Butterworth |

|

Bump/Dip Height |

0.50 inches |

|

Bump/Dip Width |

25 feet actual distance |

Note: The current versions of the McCracken profilograph software and the Ames LISA software have a filter called a blanking band filter factor or high pass filter. The filter shall be set to “0” (off) for profilograph testing unless otherwise directed by the DME.

c. Checks, calibrations, and verification of subsystems vary by manufacturer. Follow the manufacturer’s recommended procedures and frequencies at an interval no longer than the Iowa DOT’s required interval to ensure proper profile collection.

3. Test Procedure

a. The contractor (or sub-contractor) responsible for smoothness testing shall give the Project Engineer and the DME, District Materials Engineer, 48-hour notice prior to testing so the District Materials Office may provide verification testing.

- Dirt and debris may affect collection of the profile. Excessive mud or caked mud must be removed prior to testing. A grader blade or power broom will knock concrete crumbs off longitudinal or transverse grooving.

- Perform the warmup and checks of the profiler.

- For most profilers, the tire pressures should be maintained at the same pressures as when the distance was last calibrated.

- For inertial profilers it is advisable to do a bounce test and vertical height test on the sensors before beginning testing.

- Ensure computer settings are the same as when the unit was approved by the DOT. The high-pass and low pass filter settings should be “0”.

- Test in the direction of traffic whenever possible.

h. Test unit positioning and starting points.

i. On bridge decks and bridge deck overlays, the California or Ames Engineering type, 25-foot profilograph should start with the rear wheel at beginning of the bridge deck. The California or Ames Engineering type, 25-foot profilograph should stop with the front wheel at end of the bridge deck (Figure 3). If using an inertial profiler, start evaluating 16 feet onto the bridge deck. If using an inertial profiler, stop evaluating 16 feet from the end of the bridge deck.

Figure 3- wheel positioning for bridge decks.

j. When utilizing an inertial profiler on paving, begin collecting profile data for ALR 50’ before the beginning header from old to new surface and 50’ beyond the header from new to old surface. Correction of ALR determined to be beyond the control of the Contractor will be paid according to Article 1109.03, B. (See Figure 4)

k. Testing is to be done with the sensors in the wheel paths, 3 feet and 9 feet from the centerline or lane line, for lanes 11 feet to 12 feet wide unless noted otherwise in the contract documents.

l. For testing on wider lanes such as ramps and loops, position the driver side sensor 3 feet from the left edge line. If the passenger side sensors are within 1 foot of a longitudinal joint, adjust the travel path to the right so the sensor is 2 feet from the joint line.

m. For testing tapers to and from a full lane, begin or end the section testing when the pavement is either 12’ or at the full lane width whichever is less.

n. Figures 5 and 6 show examples of how to analyze ALR at obstructions defined in Article 2317.03, B, 2, b.

Figure 4-Area of Localized Roughness (ALR) at the beginning of a project. Same at the end of a project.

Note: The ALR at any point covers profile 12.5’ back and 12.5’ forward.

Figure 5-ALR Analysis at the Bridge/Bridge Approach

|

o. Follow the profiler manufacture’s recommendations with respect to run-in runouts. Most manufactures require not less than a 300-foot run-in/runout distance. The run-in allows the accelerometers, lasers, and computer to stabilize before the start of the section.

p. Either mark the intended start and stop location of the section and place reflective cones or strips to trigger the auto start/stop sensor on the profiler or utilize a GPS for accurate location determination.

q. Use the event feature to mark on the file any reference points such as side road intersections, roadway signs, maintenance markers, stations markers, and mileposts. In the event of rough segments or ALR, this will help the grinding personnel locate the area to grind. (The as driven stationing from the profiler will rarely match the stationing on the roadway unless the roadway is completely flat with no curves. The longer the run of the profiler, the farther the profiler stationing will be off from the plan stationing.)

r. During the profiler run, use the ignore feature at bridges and bridge approaches to mark areas on the file and exclude the data from the analysis. The profiler still collects data, and it can be recovered later during analysis if the key is pressed inadvertently.

s. Label the file so it can be easily found and retrieved later. (Project number, direction of traffic, lane, beginning station, ending station in the file name is one way to label)

Note: An example of best practice file name: PROF 95-0354-244 SB OL 841+00 to 625+00

t. When a segment is corrected by grinding to improve the segment MRI and/or ALR, the entire segment must be retested, and a new MRI and/or ALR shall be determined to verify that the corrected segment is in specification compliance.

Note: An example of best practice final file name: PROF 95-0354-244 SB OL 841+00 to 625+00-A (if pavement corrections were required)

u. Areas identified and corrected in accordance with 2317.04D may be reviewed by the Engineer.

4. Analyzing and Reporting

- Use the profiler software export function to export an unfiltered “ERD” file or use any other unfiltered ProVAL readable file.

- Use the latest version of ProVAL to perform the MRI and ALR analysis on the files.

- Report results on the DOT provided Excel spreadsheet (Figure 6).The sheet can be downloaded at https://iowadot.gov/construction_materials/Materials-forms. The test report is required on this form for project acceptance.

- Any areas needing correction will be noted by the software on the spreadsheet. For segments that are ground to correct the MRI, show the corrected MRI and mark the box to the left of the segment to show grinding has been completed on that spreadsheet.

- There are three types of reports:

i. Preliminary. Used by the contractor to submit the report in the timeframe required in the specifications. Any defective areas shall be identified. A final report must follow. A preliminary report is required by Specification 2317.03.B5. If no pavement corrections are required a final report may be issued in lieu of a preliminary report.

ii. Final. Used to indicate that the report is being submitted for acceptance.

iii. Corrected. Used to indicate that there was either an error in the final report or that the section was corrected by grinding and retested after the final report was issued.

- Roughness shall be reported in inches. Distance shall be reported in feet for MRI (paving) and reported in 1/1000th of a mile (0.001) for Profile Index (bridge decks).

- Test report laboratory numbers must be continuous and increasing numerically as each succeeding test is performed. Laboratory numbers shall have a letter added to the end of the original laboratory number for corrected reports

- Submit all reports to the Engineer. Submit copies of original profiler files to the Engineer. Label the file(s) with the project as part of the file name.

- Keep all original profiler files until validation of the contractor test results has been confirmed.

- Example of a completed reports form are shown in Figures 7 through 9.

Figure 7-Bridge deck report.

|

|

k. Certification -Use a trained, certified person to do the testing, evaluation, and reporting. The certification information is in Materials IM 213.

5. VALIDATION OF CONTRACTOR TEST RESULTS

a. In order to use the Contractor test results in the acceptance decision, the results must be validated by District Materials Staff.

b. The Contractor (or subcontractor responsible for testing) shall contact the appropriate District Materials office 48 hours prior, but in the case District Materials cannot be present the District Materials Office will perform verification testing within 1 month from receiving final test reports provided that the pavement is available and suited for testing. The validation tolerances are in IM 216.

c. When the Contractor test results cannot be validated, the District Materials Office will promptly notify the Contractor and begin the dispute resolution process. Testing disputes arising between the Contracting Agency and the Contractor shall be resolved in a reliable, unbiased manner. This may involve an evaluation performed by the Iowa DOT Central Materials Laboratory. Resolution decisions by the Iowa DOT Central Materials Laboratory will be final.

d. The District Materials Engineer will select some or all the following steps for the dispute resolution:

i. Check all numbers and calculations.

ii. Review testing procedures.

iii. Compare profiles and dates of testing.

iv. Check equipment operation, calibrations and tolerances.

v. Perform side-by side tests.

vi. Involve the Central Materials Laboratory.

vii. If the discrepancy cannot be resolved using the steps listed above, or if it is determined that the Contractor’s testing is in error, then the Agency test results will be used for the acceptance decision for the project.

Figure 10- Basic Geometric Elements of a Roundabout

Note: Unless otherwise specified, the greater of the length of the tapered approaches and returns, or the first 150’ of road connections are excluded from MRI and ALR evaluation.

Figure 11- Basic Geometric Elements of a Simple Ramp Curve (image from Chapter 2 of the IA DOT Design Manual)

Figure 12- Basic Geometric Elements of a Ramp Spiral (image from Chapter 2 of the IA DOT Design Manual)

|

TS=Point of change from a Tangent to a Spiral curve |

|

SC=Point of change from Spiral curve to Circular curve. |

|

CS=Point of change from Circular curve to Spiral curve. |

|

ST=Point of change from Spiral curve to Tangent. |

Figure 13-SIDE ROAD CONNECTIONS

Figure 14-Testing of patches (50-100').

Figure 15-testing of patches (100-250').

Terms and Definitions

|

Acceleration lane |

A short traffic lane designed to permit vehicles entering a road to accelerate to the speed limit of the road prior to merging with existing traffic. |

|

ALR |

the Area of Localized Roughness (ALR) based on a continuous MRI computed over a 25-foot distance as determined by the latest version of ProVAL. |

|

Auxiliary lane |

A lane other than a through lane, used to separate entering, exiting or turning traffic from the through traffic. |

|

Auxiliary lanes |

Supplemental lanes that provide additional capacity between interchange ramps or along a series of interchanges. |

|

Average Profile Index |

Total Inches divided by Total Miles for each segment. Used in Specification 2428. |

|

Corrected Report |

A report that indicates an error on the original final report has been corrected. |

|

Final Report |

A report that is submitted after the testing, evaluating and surface corrections have been done. |

|

MRI |

The index used for determining the pavement smoothness is the Mean Roughness Index (MRI) per segment as determined by the latest version of the FHWA’s software, ProVAL. |

|

Notification |

The contractor or sub-contractor responsible for smoothness testing shall give the Project Engineer and District Materials Engineer 48 hours notice prior to testing. |

|

Partial Segment |

A partial segment may result from an interruption of the continuous pavement surface with the previous adjacent segment. |

|

PI |

The Profile Index often abbreviated as the PI. Measured roughness in inches divided by the length in miles. Utilized under specification 2428. |

|

Preliminary report |

A report that is submitted prior to any surface corrections. |

|

Ramp |

A short section of road that allows vehicles to enter or exit a controlled-access highway. Defined as the area between the PC, Point of Curvature, or TS, Point of change from Tangent to Spiral curve, and PT, Point of Tangency, or ST, Point of change from Spiral curve to Tangent. |

|

Roundabout |

A roundabout, a rotary and a traffic circle are types of circular intersection or junction in which road traffic is permitted to flow in one direction around a central island. Unless otherwise specified, the first 150’ of road connections are excluded from MRI and ALR evaluation. |

|

Section |

A section of the total of all segments in a day’s run per lane. Each lane is tested and evaluated separately. |

|

Segment |

A segment is a continuous area of finished pavement of 0.100 mile in length (PI) or 528 feet (MRI) and one lane in width. |

|

Testing Direction |

Testing direction may be performed in either direction of traffic. Whenever possible, it is desirable to test and reduce traces in the direction of traffic. |

|

Travel Lane |

A lane for the movement of vehicles travelling from one destination to another, not including shoulders. |

|

Turn Lane |

A lane used primarily to separate turning traffic from through traffic. Turn lanes can also be used by vehicles as a deceleration area when leaving the major street. |