1.01 SECTION INCLUDES

A. Portland Cement Concrete (PCC) Pavement.

B. Portland Cement Concrete (PCC) Pavement Widening.

C. Portland Cement Concrete (PCC) Curbs and Gutters.

D. Portland Cement Concrete (PCC) Resurfacing.

1.02 DESCRIPTION OF WORK

A. Includes the requirements for the construction of full depth Portland Cement

Concrete (PCC) pavement, pavement widening, and concrete curbs and gutters placed

upon a prepared or corrected subgrade or previously constructed base or subbase. See

Division 2 - Earthwork and

Site Grading for subgrade and subbase construction specifications. This section shall

also include final subgrade/subbase preparation for concrete paving.

B. Includes the requirements for construction of the following PCC Resurfacing applications:

1. PCC bonded overlay placed directly on an existing full depth concrete pavement

2. PCC unbonded overlay placed on a stress relief course (bond breaker) over an existing

PCC pavement or and existing PCC pavement that has been overlaid with HMA (composite pavement).

3. Whitetopping / PCC overlay placed directly on an existing full depth asphalt pavement.

C. Reference is made to the Iowa Department of Transportation Standard Specifications for

Highway and Bridge Construction, Series 2001, and all current General Supplemental Specifications

and Materials Instructional Memorandum by the term “Iowa DOT Specifications” and/or “Iowa DOT I.M.”

D. The work shall include all labor, equipment, and materials necessary to complete the paving

as specified in the contract documents.

1.03 SUBMITTALS

A. Submit under provisions of Division 1.

B. PCC Mix Design: Mixes are Class C, M, C-V47B, and M-V as defined in Iowa

DOT 2301 and I.M.

529. Unless otherwise specified in the contract documents, maturity method for strength

determination prior to opening to traffic will be allowed. Class A shall be used for concrete

base or temporary pavement and recreational trails only. Class B shall be used for temporary

pavement and recreational trails only. After October 31 all Class B concrete will be replaced

with Class A concrete. In cases where early opening of pavement is desirable, the contract

documents may require the use of Class M, or M-V concrete mixtures or may require using Type

III cement with other concrete mixtures. Such sections of pavement may be opened to traffic

in accordance with the limitations of Section 7010, 1.07.I.

1. Two weeks prior to commencing any Portland concrete placement, the Contractor shall

submit a paving mix design for each different source of aggregate to be used for review

and approval by the Jurisdictional Engineer. Mixes or mix designs approved by the Iowa

Department of Transportation or an independent testing laboratory shall be submitted.

2. Submit all testing and certifications in accordance with Section 7010,

3.14.

C. Upon requests the Contractor will provide Material Certifications to the Jurisdictional Engineer.

1.04 SUBSTITUTIONS

A. Use only materials conforming to these specifications unless permitted otherwise by

Jurisdictional Engineer and shown in the contract documents.

B. Obtain approval of Jurisdictional Engineer for all substitutions prior to use.

1.05 DELIVERY, STORAGE, HANDLING, AND SALVAGING

A. Aggregate Storage: Prevent contamination and frequent variations in specific gravity,

gradation, or moisture content; Iowa DOT 2301.

B. Concrete transported without continuous agitation shall not be used if the period elapsed

between the time the concrete is mixed and the time it is placed is greater than 30 minutes;

Iowa DOT 2301. With the approval of the Jurisdictional

Engineer, an approved retarding admixture may be used at the rate prescribed in Materials

I.M. 403 and the mixed-to-placed time may be extended

by an additional 30 minutes.

C. Concrete transported with agitation shall not be used when the cement has been in contact

with the aggregate more than 90 minutes before it is placed;

Iowa DOT 2301. With the approval of the Jurisdictional Engineer, an approved retarding admixture

may be used at the rate prescribed in Materials I.M. 403.

D. Concrete containing Type III cement and transported with agitation shall be delivered and

placed within the following time limits:

Concrete Temperature

(at time of

mixing, degrees F) |

Maximum Time

(from mixing to placement, in min.) |

| 75 or less |

60 |

| 76 to 85 |

45 |

| above 85 |

30 |

E. The methods of delivering and handling the concrete shall be such that objectionable

segregation or damage to the concrete will not occur, and that which will facilitate placing

with a minimum of rehandling; Iowa DOT 2301.

F. The compartment in which concrete is transported to the work shall be thoroughly

cleaned and flushed with water to ensure that hardened concrete will not accumulate.

Flushing water shall be discharged from the compartment before it is charged with the

next batch; Iowa DOT 2301.

G. Cement and Fly Ash: Store in suitable weatherproof enclosures;

Iowa DOT 2301.

H. Admixtures: Store in suitable weather tight enclosures which will preserve quality.

I. Reinforcing Steel: Store off ground on timbers or other supports.

1.06 SCHEDULING AND CONFLICTS

A. Construction Sequence:

1. Attend a preconstruction meeting unless not required by Jurisdictional Engineer.

2. Submit plan for construction sequence and schedule prior to commencing construction.

B. Conflict Avoidance:

1. Expose possible conflicts in advance of construction, such as utility lines and

drainage structures. Verify elevations and locations of each and verify clearance for

proposed construction.

2. Complete elements of the work which can affect line and grade in advance of other

open cut construction unless noted on plans.

3. Notify Jurisdictional Engineer of conflicts discovered or changes needed to accommodate

unknown or changed conditions.

C. Traffic Control Plan: The Contractor shall develop a traffic control plan based on

the Manual on Uniform Traffic Control Devices (MUTCD). Traffic control plans that are provided

in the contract documents shall be reviewed by the Contractor and all traffic control devices

used shall be in accordance with the MUTCD.

D. Stop Work: Stop work and notify Jurisdictional Engineer immediately if contaminated

soils, historical artifacts, or other environmental or historic items are encountered.

E. Conform to Local, State, and Federal Requirements.

1.07 RESTRICTIONS ON OPERATIONS

The following shall apply unless specifically modified by the Jurisdictional Engineer.

A. Weather Conditions:

1. Do not place concrete when stormy or inclement weather or temperature prevents good

workmanship. Aggregates containing frozen lumps shall not be placed, and concrete

shall not be placed on a frozen subgrade or subbase. The contractor will take all necessary

actions to prevent the pavement from freezing.

a. Concrete placement may commence if the concrete mix temperature is a minimum

of 40º and the air temperature is:

1) After November 15, the air temperature is 36º and rising.

2) After April 15, the air temperature is 32º and rising.

b. Concrete placement will stop when:

1) After November 15, the air temperature is 37º and falling.

2) After April 15, the air temperature is 32ºand falling.

3) With non-reinforced pavement, calcium chloride may be added to the

mixing water to hasten initial set, if approved by Jurisdictional Engineer.

4) Pavement damaged by inclement weather shall be removed and replaced.

c. For warm weather, restrictions on concrete placement see

Section 7010, 1.07, D.

2. Temperature restrictions and protection requirements may be modified by the

Jurisdictional Engineer under unusual conditions.

B. Night Conditions:

1. Do not place or finish concrete under artificial light, unless approved by the

Jurisdictional Engineer.

2. In good weather, the header shall be placed at least 45 minutes before sunset.

3. In cold weather, more time must be allowed for finishing and protection.

4. All finishing and covering operations shall be performed prior to darkness.

5. Temperature restrictions and protection requirements may be modified by the

Jurisdictional Engineer under unusual conditions.

C. Cold Weather Temperature Protection:

1. All concrete pavement and curb/gutters, including exposed edges of the slab and

curb, shall be protected cured. In

addition, concrete less than 36 hours old shall be protected as follows:

TEMPERATURE FORECAST

TYPE OF PROTECTION |

TEMPERATURE |

TYPE OF PROTECTION |

35º to 32ºF |

One layer of burlap for concrete. Plastic

top layer is required if burlap is exposed to rain or heavy winds. |

31º to 25ºF |

Two layers of burlap or one layer of plastic

on one layer of burlap. |

Below 25ºF |

Four layers of burlap between layers of four

mil plastic or equivalent commercial insulating material |

Use of straw shall not be allowed for temperature protection. |

|

Night Temperature Forecast |

Type of Protection1 |

|

35º to 32ºF |

One layer of burlap for concrete. |

|

31º to 25ºF |

Two layers of burlap or one

layer of plastic on one layer of burlap. |

|

Below 25ºF |

Four layers of burlap between

layers of 4 mil (100 μm) plastic or equivalent commercial insulating material approved by

the Jurisdictional Engineer |

1 The protection shall

remain until one of the following conditions is met:

a. The pavement is 5 calendar days old.

b. Opening strength is attained.

c. Forecasted low temperatures exceed 35ºF for the next 48 hours.

d. Forecasted high temperatures exceed 55ºF for the next 24 hours and subgrade

temperatures are above 40ºF. |

a. The protection shall remain until the pavement is 5 days old or a

minimum of 24 hours and compressive strength of 500 psi. Paving

operations shall be shut down in time to comply with protection requirements outlined above. In

good weather, the header shall be placed at least 45 minutes before sunset. During cold weather,

more time must be allowed for finishing and protection. All finishing and covering operations

shall be performed prior to darkness. Temperature restrictions and protection requirements may

be modified by the Engineer.

b. When the pavement is placed directly on natural subgrade, earth check dams shall be

constructed immediately after passage of the slip forms or removal of the forms to prevent

water form flowing along the edge of the pavement and undermining the slab. They shall not

be spaced or be of a width to provide an approach over which a vehicle may be driven onto

the pavement

bc. Equivalent commercial insulating material

approved by the Jurisdictional Engineer may be used. This material shall be waterproof and have

a minimum R value of 0.50. If initial set has not yet occurred, a layer of burlap shall be placed

on top of concrete prior to placing insulating blankets.

cd. Vertical edges of pavement and back of curbs

shall be cured by the same method used for curing the surface.

de. Method of protection and materials used shall

maintain the concrete above 40°F.

D. Concrete Evaporation Protection:

1. Hot weather condition is defined as any combination of the following conditions

that tend to impair the quality of plastic concrete by accelerating the rate of moisture

loss and rate of cement hydration causing thermal shrinkage and resulting in plastic

shrinkage cracking or crazing.

| · High Ambient Temperature |

· High Wind Velocity |

| · High Concrete Temperature |

· Solar Radiation |

| · Low Relative Humidity |

|

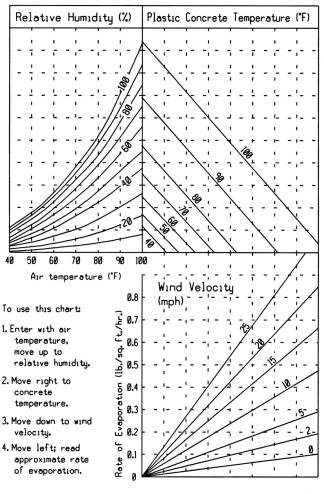

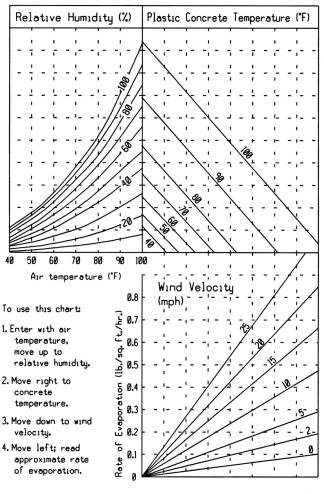

2. Concrete evaporation protection will be based on the theoretical rate of surface

evaporation when it exceeds 0.1 lbs. per square foot per hour. The National Weather

Service’s maximum air temperature, relative humidity and maximum steady wind velocity

without gusts, for the date and the location of the paving pour shall be used for the

Theoretical Rate of Evaporation Chart.

THEORETICAL RATE OF EVAPORATION CHART

3. During hot weather conditions the Jurisdictional Engineer may restrict concrete

placement to early morning or evening hours.

4. Under hot weather conditions the Contractor will advise the Jurisdictional

Engineer of the results of the theoretical evaporation rate throughout paving operations.

The Contractor shall discontinue with placement of the concrete when the theoretical

evaporation rate exceeds to 0.30 lbs./sq.ft./hr.

6. The protection practice by the Contractor will be as follows for the evaporation rate

greater then 0.1 lbs./sq.ft./hr.

a. Immediately apply an approved evaporation retarder (Polymers) to the concrete

pavement and curbs or increase the application cure to 1.5 times the standard specified

rate.

b. Take special precautions to assure that the forms and subgrade are sufficiently

moist or protected to avoid lowering the water content at the pavement/subgrade interface.

In hot weather conditions the subgrade should also be moistened the evening before operations.

c. Assure that the time between placing and curing is minimized and eliminate delays.

d. Moisten concrete aggregates that are dry and absorptive.

e. Use a fog spray to raise the relative humidity of the ambient air if there is a

delay in immediately applying the curing compound.

f. Minimize solar heat by shading, wetting or covering concrete chutes or other

equipment that comes in contact with plastic concrete.

g. If shrinkage cracks should appear during finishing the cracks can be closed by

striking each side of the crack with a float and refinishing.

E. Rain Protection:

1. The Contractor shall have available, near the site of the work, materials for

proper protection of the edges and surface of concrete. Protective material may consist

of sheets of burlap, or plastic film. Planks or other material with suitable stakes that

can be used as temporary forms shall also be on hand;

Iowa DOT 2301.

2. If initial set has not occurred, contractor shall take every precaution necessary

to protect the surface texture of the concrete.

3. Failure to properly protect concrete shall constitute cause for removal and replacement

of defective pavement, if so determined by the Jurisdictional Engineer.

F. Safety Fence for Pavement:

1. The Contractor shall insure that all traffic control devices are in place in accordance

with the Traffic Control Plan.

2. At the end of each day's run and at all side streets, the Contractor shall erect

and maintain such barriers and fencing as are necessary to protect the pavement from damage.

3. Intermediate safety fences may be required for the purpose of opening the slab for

access to a side road, side street, or entrance.

G. Repair of Pavement:

1. The Contractor shall protect the new pavement and its appurtenances from traffic,

both public and that caused by its own employees and agents, at its expense. This includes

the erection and maintenance of warning signs, lights, barricades, watchmen to direct traffic,

and pavement bridges or crossovers.

2. Any part of the pavement damaged by traffic or other causes occurring prior to

final acceptance of the pavement shall be repaired or replaced, at the discretion of

the Jurisdictional Engineer, at the Contractor's expense.

3. The Contractor shall not operate equipment with metal tracks, metal bucket blades,

or metal motor patrol blades directly on new paving. The Contractor shall not unload soil

or granular materials, including base rock for storage and future reloading directly onto

new paving.

H. Utilities Protection:

The Contractor will not start work until all utilities are located.

1. Repairs: When the Contractor disrupts or breaks known utilities of the Jurisdiction

or privately owned utilities, such utilities shall be repaired at the Contractor's expense.

Unnecessary delays in making repairs shall cause the Jurisdictional Engineer to have such

repairs made and the cost thereof deducted from the monies due the Contractor.

2. Drains, Pipe, Tiles: Existing subsurface drains, pipe, and tiles, which are disrupted

or broken by reason of the construction shall be connected to the storm sewer, or another

adequate outlet if storm sewer is not available. Should no outlet be readily available, the

Jurisdictional Engineer shall determine a suitable solution.

3. Water Stop Boxes and Services: The adjustment of stems and castings and/or repair of

those broken or damaged by the Contractor shall be at the contractor's expense. Relocation

of stop boxes and services shall be by bid items.

I. Use of Pavement: Time for opening pavement for use is determined

by age or by test results from cylinder or beams taken during placement.

| MINIMUM AGE OR STRENGTH

OF PAVEMENT BEFORE OPENING |

| Class of Mix |

Type of Cement |

Minimum Age For Opening without Testing(4) |

Minimum Compressive Strength (psi) |

(1)Minimum Flexural Strength Center Point (psi) |

| A |

Type I |

14 Days(2) |

3,000 |

500 |

| B |

Type I |

14 Days |

2,400 |

400 |

| C |

Type I |

7 Days(3) |

3,000 |

500 |

| C |

Type III |

48 Hours |

3,000 |

500 |

| M |

Type I |

48 Hours |

3,000 |

500 |

| C-V47B |

Type I |

7 Days(3) |

3,000 |

500 |

| C-V47B |

Type IP |

7 Days(3) |

3,000 |

500 |

| M-V |

Type I |

48 Hours |

3,000 |

500 |

| M-V |

Type IP |

48 Hours |

3,000 |

500 |

(1) Optional test method for primary roads.

(2) Ten days for concrete 8 inches or more in thickness.

(3) Five days for concrete 9 inches or more in thickness.

(4) Opening without testing only allowed upon approval of Jurisdictional Engineer.

Note: Maturity Method may be allowed with approval of the Jurisdictional Engineer;

I.M. 383 |

J. Restrictions on PCC Overlays and Whitetopping:

1. At temperatures below 55°F, the opening time shall be determined using the maturity method

2. PCC Overlay and Whitetopping concrete shall not be placed when the air temperature is below 40°F.

3. Bonded concrete overlays shall be placed between June 1 and September 30.

4. Unbonded overlays and Whitetopping materials shall not be placed on any HMA when the

pavement surface temperature exceeds 120° F.

All measurements for payments will be made by the Jurisdictional Engineer or authorized

representative.

The quantity of the various items of work involved in construction of concrete pavements

will be measured in accordance with the following provisions.

A. Portland Cement Concrete Pavement: The method of measurement

described herein for portland cement concrete pavement applies to standard or slip form portland

cement concrete pavement, reinforced portland cement concrete pavement and portland cement concrete

base.

1. The area of pavement constructed of the type, class, and thickness specified

shall be computed in square yards from surface measure longitudinally and the nominal

pavement width including integral curb.

2. No deductions shall be made for intakes, manholes or other castings.

3. The area of street returns, paved crossovers, and other similar irregular

areas shall be determined from field measurements using the edges of the main line

pavement as terminals.

4. Pavement Protection: Surface curing and temperature protection covering are

considered incidental to the concrete pavement bid item.

B. Barrier Curb: Barrier curb shall be measured in linear feet.

C. Integral Curb: Construction of integral curb shall be incidental to the construction

of concrete pavement and included in the pavement surface measured for payment.

D. Curb and Gutter: Measurement shall be in linear feet measured along the face of

curb placed unless specified on the plans as incidental with the street paving.

E. Incidental Concrete: Miscellaneous sections of concrete that are required to be

constructed, but not listed as separate bid items, are to be considered incidental to other

concrete bid items and will not be paid for separately. Examples are headers, etc.

F. Concrete Median: Unless otherwise provided, the Jurisdictional Engineer shall

compute in square yards the area of median constructed from measurements of the length along

the surface and the overall width of median. When curb is integral with the pavement the width

shall be measured from back to back of the integral curb.

G. Fixture Adjustment: Refer to Section 2010 for Measurement

and Payment of Fixture Adjustment.

H. Portland Cement Concrete Pavement Samples and Testing: Furnish hardened Portland

Cement Concrete Pavement Samples and testing results required in Section 7010,

3.14. The Contractor will be paid for thickness, smoothness (except 10-foot straight edge)

and strength measurements and testing at the lump sum contract price. This payment shall be full

compensation for furnishing all such samples and test results to the Jurisdiction where required.

All other items listed in Section 7010, 3.14 under the Contractor's responsibility will be considered

incidental to this pay item.

I. Saw Cut: Saw cuts for construction joints in new pavement shall not be measured for

payment.

J. Safety Fence for Pavement: Safety fence for pavement under Section 7010,

1.07, F shall not be measured for payment.

K. Driveway Surfacing Material: The quantity of granular surfacing placed on intersecting

roads, drives, and turnouts shall be computed in tons or in cubic yards as indicated in the contract

documents. The excavation necessary for placement of this material will be incidental to the work

and shall not be measured for payment.

L. Portland Cement Concrete Pavement Widening:

1. The quantity of PCC widening shall be computed in square yards by the Jurisdictional

Engineer from the surface width of widening specified in the contract document and measured

length of the edge of the old pavement.

2. Measurement shall include the widening and all other work not paid for under other items.

M. Concrete Thickness Pay Factor:

1. The bid amount for portland cement concrete pavement shall be adjusted by a "Concrete

Thickness Pay Factor" before final payment is made. If there is a deficient pavement

thickness on a private development project that is intended to be accepted into the jurisdiction

street system, the Jurisdiction will receive the penalty payment prior to acceptance of the work.

2. On the basis of the core lengths, street pavements will be classified in the following bands:

BAND LIMITS |

| Band 1 |

Pavement of design or greater thickness

or deficient by not more than 0.15 inch. |

| Band 2 |

Pavement deficient in thickness by

more than 0.15 inch, but not more than 0.25 inch. |

| Band 3 |

Pavement deficient in thickness

by more than 0.25 inch, but not more than 0.50 inch. |

| Band 4 |

Pavement deficient in thickness by

0.51 inch or more. |

N. Thickness Cores:

1. One four-inch core shall be taken initially for each section of approximately

one thousand (1,000) square yards.

2. For any core outside of Band 1, two additional cores shall be taken in that

section of pavement, and the average of the three cores shall be used.

3. Core locations shall be selected at random by the Jurisdictional Engineer.

4. On widening projects, the Jurisdictional Engineer shall be consulted in the

selection of core locations in an effort to obtain representative cores and avoid

the occasional special locations where corrective measures have been taken only in

the finishing of the concrete in an effort to improve the general profile.

5. It shall be assumed that each original core or additional core is representative

of the pavement thickness for a distance extending one-half the distance to the next

core, measured along center line, or in the case of an initial or final core, the

distance will extend to the end of the pavement section.

6. Irregular Section:

a. The drilling of cores in irregular sections, or on projects involving less

than 2,500 square yards of pavement, base, base widening, or pavement widening,

may be waived by the Jurisdictional Engineer, in which case the designed thickness

will be considered as the measured thickness.

b. If the work is cored, the applicable provisions above shall prevail, except

that a determination of pavement thickness shall not be made on any project on the

basis of less than three cores, and in the case of widening, a given core shall

represent only one lane of pavement, and a minimum of three cores shall be taken

for each lane.

7. At the direction of the Jurisdictional Engineer, the Contractor shall cut samples

from the finished pavement or other course by drilling with a core drill of a size that

will provide samples of a 4 inch outside diameter.

8. Core holes shall be restored by tamping low slump concrete into the hole, and

finishing and texturing the surface. Cores shall be identified and delivered to the

field laboratory or Jurisdictional Engineer.

9. On the basis of core lengths, the pavement or various sections of pavement shall

be classified in the following bands. Core lengths shall be measured as outlined in

IM 347.

| PAY FACTOR FOR CONCRETE

THICKNESS |

| BAND |

PAY FACTOR |

| 1 |

1.00 |

| 2 |

.95 |

| 3 |

.85 |

| 4 |

As determined by the Jurisdictional

Engineer |

10. The Jurisdictional Engineer shall study the extent and severity of the

deficiencies of pavement areas for Band 4. Depending on the severity, the

Jurisdictional Engineer shall require one of the following procedures:

a. The deficient areas shall be removed at the Contractor's expense and

replaced with pavement meeting the contract requirements.

b. A mutually acceptable agreement may be negotiated between the contractor

and the Jurisdictional Engineer which provides a combination of an extended

guarantee period and payment penalty and allows the pavement for the area in

question to be left in place.

O. Pavement Smoothness:

1. Local Streets and Minor Collectors: The costs of correcting the smoothness and

associated traffic control shall be incidental to the cost of pavement. No pavement

smoothness incentives will be provided.

2. Non-Primary Arterials and Major Collectors: The cost of correcting the smoothness

and associated traffic control shall be incidental to the cost of pavement. Price reductions

imposed for noncompliance with the specifications will follow schedule B of Iowa

DOT 2316. No pavement smoothness incentives

will be provided unless specified in the contract documents.

3. Primary Roads: The cost of correcting the smoothness and associated traffic

control shall be incidental to the cost of pavement. Price reductions imposed for

noncompliance with the specifications will follow schedule A of Iowa

DOT 2316.07. Pavement smoothness

incentives will be provided unless otherwise specified in the contract documents.

P. Portland Cement Concrete Resurfacing

1. PCC Resurfacing, Furnish Only: For the number of cubic yards of PCC incorporated

in the work, the Contractor shall be paid the contract unit price per cubic yard. This

payment shall be full compensation for furnishing the concrete mixture and all materials

therefor and for delivery to the grade.

2. PCC Resurfacing, Place Only: For the number of square yards of PCC pavement resurfacing

constructed, the Contractor will be paid the contract unit price per square yard. This payment

shall be full compensation for placing, finishing, protecting and curing the pavement, for

sawing and sealing joints for furnishing and installing reinforcement, for preparation of the

pad line and subgrade, and for meeting all other requirements of Section

7010.

3. Scarification for PCC Resurfacing and Whitetopping: For the number of square yards of

pavement scarified in preparation for PCC Resurfacing or Whitetopping, the Contractor shall

be paid the contract unit price per square yard.

4. Surface Preparation for PCC Resurfacing (Bonded PCC Overlay): For the number of square

yards of pavement prepared by sandblasting or shot blasting, followed by surface cleaning,

the Contractor shall be paid the contract unit price per square yard.

5. Stress Relief Course (Unbonded PCC Overlay): Shall be bid, measured, and paid for in

accordance with Section 7020, 1.04.

2.01 TYPE OF PAVEMENT

Concrete pavement shall be one of two types, standard or slip form.

A. Standard Concrete Pavement: Standard concrete pavement may be reinforced, or

nonreinforced, as noted in the contract documents and shall consist of concrete of the class

specified in the contract documents, reinforced as shown in the contract documents, placed

within forms, and consolidated and finished by equipment operating on forms.

B. Slip Form Pavement: Slip form pavement may be reinforced, or nonreinforced, and

shall consist of concrete of the class specified in the contract documents, reinforced as shown

in the contract documents, placed, consolidated, and finished without the use of fixed forms.

2.02 MATERIALS

A. Portland Cement; Iowa DOT 4101 and

I.M. 401

1. Portland cement shall meet the requirements of AASHTO M 85 specifications for

the type of cement required. Cement which contains 5.0 percent or more of lumps retained

on a No. 20 sieve shall be rejected.

a. Cement which contains less than 1.0 percent of lumps may be used without

adjustment in batch weights. For each 1.0 percent or fraction thereof from

1.0 to 5.0 percent of lumps found by test, batch weights of cement used in

either concrete pavement shall be increased by 2.0 percent of the original value.

b. Cement stored at the site of the work or local warehouses for more than 60 days,

or cement stored in producer's silo more than a year shall be retested for lumps before

using.

2. Type I; Normal Portland Cement:

a. Unless otherwise specified, cement shall meet Type I AASHTO M 85, Type I.

b. When the addition of fly ash to Type I cement is allowed in accordance with

Iowa DOT 2301, or AASHTO M 240, Type I (PM) or Type IP, cement may be furnished

and used within the same limitations.

c. The cement content of the concrete shall be that specified for Type I cement.

B. Mineral Additives:

1. Fly Ash Substitute

a. The use of fly ash may be substituted for Portland Cement in a Portland Cement

Concrete mixture if approved by the Jurisdictional Engineer and shall conform to the

requirements of Iowa DOT 4108,

I.M. 529, and I.M.

491.17. Iowa DOT 2301 shall also apply except

that fly ash substitution rates shall follow the table given in

Section 7010, 2.03

E.

b. Fly ash to be substituted for Portland cement in concrete shall comply with AASHTO M 295,

either Class F or Class C, including the Supplementary Optional Chemical Requirements. Sources

with fly ash between 1.5 percent and 2.5 percent available alkalies may be approved. For Class

C fly ash, the pozzolanic activity test with lime will not be required.

c. Approval of the source of fly ash will be required. This is to be based on fly ash

produced when the power plant is using specific materials, equipment, and processes. Any

change in materials, equipment, and processes shall void the source approval, and a new

approval of the source will be required.

d. Inspection and acceptance of fly ash will be in accordance with Iowa

DOT Materials I.M. 491.17.

2. Ground Granulated Blast Furnace Slag Substitute

a. GGBFS may be substituted for Portland cement in Portland cement concrete

mixes if approved by the Jurisdictional Engineer and shall conform to the

requirements of Iowa DOT 2301,

4108,

I.M. 529 and I.M. 491.14.

b. Inspection and acceptance of GGBFS will be in accordance with Iowa DOT

MaterialsI.M. 491.14, appendix A.

C. Fine Aggregate for Concrete, Iowa DOT 4110:

Clean, hard, durable mineral aggregate particles free from detrimental amount of silt, shale, coal,

or organic matters.

1. Natural sand as a result from disintegration of rock through erosional processes.

2. From an approved source of not more than 2.0 percent shale and coal particles retained

on a No. 16 sieve; not more than 2.5 percent silt by weight.

3. Gradation: Iowa DOT 4109, gradation

No. 1.

| Sieve Size |

Percent Passing |

| 3/8 inch |

100 |

| No. 4 |

90 to 100 |

| No. 8 |

70 to 100 |

| No. 30 |

10 to 60 |

| No. 200 |

0 to 1.5 |

| Jurisdictional Engineer may adjust

gradation to allow for use of local aggregates. |

D. Coarse Aggregate for Concrete, Iowa DOT 4115:

Coarse aggregate shall consist of crushed stone particles.

1. Abrasion loss, in accordance with AASHTO T 96 shall not exceed 50.

2. Freeze and thaw loss, in accordance with Iowa DOT Test Method 211, Method A,

shall not exceed 6 percent.

3. Objectionable Materials: The percentage of such materials shall not exceed the

following percentages:

| Objectionable Materials |

Percent |

| Clay lumps |

0.5 |

| Coal and carbonaceous shale |

0.5 |

| Total of all shale, similar objectionable

materials, and coal combined. |

1.0 |

| Sticks (wet weight) and other organic

materials, except coal. |

0.1 |

| Unsound chert particles retained on

3/8" sieve (Nonstructural concrete) |

3.0 |

| Unsound chert particles retained on the

No. 4 sieve (Gradation No. 6) (½" nominal maximum size) |

0.5 |

| NOTE: Chert particles which

break into three or more pieces when subjected to the freezing and thawing test will

be considered unsound. |

Chert in aggregate produced

from limestone sources is defined as unsound when any of the fractions of the crushed

or uncrushed chert do not meet the soundness requirements. |

4. Durability: Soundness - Iowa DOT Test Method 408-A.

a. Class 2 durability for local and minor collectors; some stone deterioration within 20 years.

b. Class 3 durability for major collectors and arterials; little to no stone deterioration within

20 years.

c. Class 2 durability stone shall be used unless stated otherwise in the contract documents or

otherwise specified by the Jurisdictional Engineer.

5. Gradation: Iowa DOT 4109,

Gradation No. 3.

| Sieve Size |

Percent Passing |

| 1 ½ inch |

100 |

| 1 inch |

95 to 100 |

| ½ inch |

25 to 60 |

| No. 4 |

0 to 10 |

| No. 8 |

0 to 5 |

| No. 200 |

0 to 1.5 |

| Jurisdictional Engineer may

adjust gradation to allow for use of local aggregates. |

E. Water Requirements: Iowa

DOT 4102.

1. Free from detrimental amounts of oil, salts, acids, strong alkalis, vegetable

matter, or other materials detrimental to concrete; AASHTO T 26. If practicable, potable

water shall be used.

2. Suspended matter in excess of 2000 ppm shall be filtered or otherwise clarified.

3. Hardness not more than 750 ppm, as calcium carbonate.

4. Methyl orange, alkalinity, not more than 1,000 ppm, as calcium carbonate.

5. Phenolphthalein alkalinity, not more than one-half the methyl orange alkalinity,

as calcium carbonate.

6. Total acidity, not more than 100 ppm as calcium carbonate.

7. Potable water obtained from a municipal supply, suitable for drinking, may be

accepted without testing.

F. Air Entrainment Admixture: Iowa DOT 4103,

I.M. 403, AASHTO M 154. Provisions shall be made to stir,

agitate or circulate air entraining admixtures prior to use so as to insure a uniform and

homogeneous mixture.

G. Admixtures: All liquid admixtures as listed below must meet the following requirements.

Other admixtures may be used subject to the approval of the Jurisdictional Engineer.

1. Retarding and Water Reducing Admixtures: Iowa DOT

4103, I.M. 403, AASHTO M194.

a. The retarding and water reducing admixture used shall be compatible with the air

entraining agent used.

b. The admixtures shall be used in amounts recommended by the manufacturer for

conditions which prevail on the project.

c. When used, they shall be introduced into the mixer after all other ingredients

are in the mixer.

d. Retarding and water reducing admixtures shall be agitated prior to and during

their use.

e. When fly ash is used in the concrete, the liquid admixture dosage shall be applied

to both the cement and fly ash weight combined.

2. Accelerating admixtures (calcium chloride): Iowa DOT

2529.

a. When calcium chloride is required, it shall be furnished at the job site.

b. Calcium chloride solution shall be a commercial 32 percent solution or equivalent,

prepared by the Contractor as follows:

| |

lbs. solid

per gallon

of water |

Solution produced

per gallon

of water |

| Type 1 - Regular Flake (77% material) |

7 |

1.35 |

| Type 2 - Concrete Flake or pellets (94% material) |

5 |

1.18 |

c. The solution shall be added at a maximum rate of 2.75 gallons per cubic yard of concrete.

d. Mixture shall be agitated until the calcium chloride is completely in solution and agitation

shall be continued, as necessary, to maintain uniformity.

H. Reinforcing Steel:

1. Deformed Bars: Billet steel bar, Iowa DOT 4151.

a. All deformed bars shall be epoxy coated, Iowa DOT

4151.

b. Tie bars shall be bent back reasonably straight. Tie bars broken during rebending shall

be replaced by the Contractor at no cost by drilling a hole and setting the bar in epoxy. Tie

bars shall meet the requirements of ASTM A 615 Grade 40 or 60.

c. All damage to epoxy coated bars shall be repaired by an approved patching material.

2. Plain Bars, carbon steel, ASTM A 306 663, Grade

40. Epoxy coated complying with Iowa DOT 4151.

3. Smooth Dowel Bars, carbon steel, ASTM A 615, grade 40 fabricated from plain bars cut

without deformation of ends; Iowa DOT 4151.

a. Epoxy coated complying Iowa DOT 4151.

b. Dowels, with exception of end of run and header joints, shall be furnished in approved

assemblies.

c. Sawed ends of dowels shall be free of burrs and projections. Sawed ends need not be coated.

d. Assemblies dipped in MC-70, RC-70, RC-250, CRS-1, CRS-2, CSS-1H, HFMS-2, HFMS-2H, or HFMS-2S

prior to delivery to work site.

4. Welded Wire Fabric, Iowa DOT 4151, ASTM A 185.

a. Epoxy coated complying Iowa DOT 4151.

b. Used as conventional reinforcement shall be of the size and spacing shown in the contract documents.

I. Expansion Tubes: Iowa DOT 4191; Fabricated

steel or plastic tubes closed on one end; tubes to be with internal diameter 1/16 inch larger than dowel

bar; bar stop capable of withstanding twenty pounds push, minimum. The stop shall be located at least 2 3/4

inches from the open end of the tube. That part of the tube between the stop and the closed end shall be not

less than the width of the expansion joint.

J. Metal Keyways: Iowa DOT 4191; Fabricated 24 gage

sheet steel; provide lengths in multiples of tie bar spacing; punch at the centerline to receive tie bars;

support metal keyway with legs unless installed by paving machine. Keyways formed on the grade during the

paving operation may be of coated or uncoated sheets of 26 gage iron or steel.

K. Supports for Reinforcing Steel: Iowa DOT 2301.

1. Support tie bars as required to place and maintain correct location during construction.

2. Support dowel bars at expansion and contraction joints.

3. Epoxy Coated Reinforcement: Support with epoxy coated or plastic chairs; tie with plastic

coated tie wires.

L. Joint Fillers and Sealers:

1. Contraction Joint Sealers: Material for sealing sawed contraction and center line joints and

other joints, as shown in the contract documents, shall meet the following requirements:

a. Poured Joint Sealer: Iowa DOT 4136. Hot

poured joint sealer shall be composed of petropolymers and be supplied in solid form.

The sealer shall meet requirements of ASTM D 3405 with the following modifications:

1) Penetration of 90 - 150 at 77 degrees F (25 degrees C).

2) Bond at -20 degrees F (-29 degrees C) standard specimen, 3 cycles, 200% extension, Passes.

b. Cold applied joint sealers meeting the above physical requirements may be used with the

approval of the Jurisdictional Engineer.

2. Preformed Expansion Joint Filler and Sealer: Preformed material for filling expansion

joints shall be one of the following types. When the type is not specified, resilient filler

shall be used.

a. Resilient Filler: Iowa DOT 4136, AASHTO M 213.

Resilient filler shall be furnished in strips of dimensions shown in the contract documents.

1) When the self expanding type is specifically required, the material shall meet

requirements of AASHTO M 153, Type III.

2) Sealer used with these fillers shall meet requirements of

Iowa DOT 4136 or shall be two component,

synthetic polymer type meeting requirements of ASTM D 1850.

b. Polyethylene Joint Filler: Iowa DOT

4136, AASHTO T 42.

1)Polyethylene joint filler shall be resistant to petroleum derivatives

and comply with the following requirements:

a) Compression: 45 p.s.i. maximum

Recovery: 90% minimum

Extrusion: 0.25 inches maximum

2) Sealer used with this filler shall be a two component, synthetic polymer

type meeting requirements of ASTM D 1850.

c. Elastomeric Joint Seals: Iowa DOT 4136,

AASHTO M 220.

1) Elastomeric joint seals shall be of the size and shape designated in the

contract documents.

2) Seals with splices shall be acceptable only when splices are made using

factory type methods. A splice shall not occur within one foot of a sharp bend,

when placed in final position, and no piece shall have more than one splice.

d. Preformed Urethane Foam Expansion Joint Filler:

Iowa DOT 4136, I.M. 436.

1) Preformed urethane foam expansion joint filler shall be made with a semi-open

cell, flexible polyurethane foam which is molded to such cross sectional shape that

it can be easily installed in a 3¼ inch to 4¼ inch wide pavement joint with parallel

sides and shall be sufficiently self locking to prevent the material from floating

out of the joint.

2) The joint filler may be produced in any convenient lengths in excess of 4 feet

and shall have the following cross sectional dimensions:

Top Width 4½ inches plus or minus 1/8 inch

Overall depth 7-3/4 inches plus or minus ½ inch

3) A lubricating adhesive, recommended by the manufacturer for the intended use,

shall be provided with the joint filler.

4) The properties of the urethane foam when determined on skin free specimens

shall meet the following requirements:

Density: 6.5 to 10.0 lb. per cu. ft.

Compressive load, 50% deflection: 20.0 psi, max.

Recovery: 95% min.

Water absorption: 35% by volume, max.

Chemical Resistance. The material shall be resistant to petroleum solvents and linseed oil.

M. Liquid Curing Compounds: Iowa DOT 4105,

AASHTO M 148.

1. Compounds shall be of such consistency that they can be readily applied by

spraying to a uniform coating at a material temperature above 40 degrees F.

2. Moisture Retention shall meet this requirement of Iowa DOT Material Laboratory

Test Method 901.

3. Liquid curing compounds shall dry to the touch in not more than 4 hours.

After 12 hours, the compounds shall not track off the concrete when walked upon.

4. White Pigmented Compounds. Iowa DOT

4105.

a. Shall consist of finely ground, white pigment and vehicle, ready mixed for

use without alteration.

b. The pigment shall not settle excessively or cake in the container.

c. After the compound sprayed on a test slab has dried, it shall have an apparent

daylight reflectance not less than 60 percent relative to magnesium oxide.

d. The compound shall be agitated just prior to being removed from the container

and continuously during application.

5. Dark colored compounds shall consist of asphalt emulsion or asphalt cut back

with a volatile solvent and shall contain not less than 50.0 percent asphalt.

N. Burlap Covering: Iowa DOT 4104.

1. Jute and manilla fibers shall weigh not less than 10 ounces per square yard.

2. Shall be new material or reclaimed material which shall not have a deleterious

affect upon fresh concrete.

O. Pavement Seals: Linseed Oil Emulsion.

1. Shall be non-pigmented and homogenized to produce uniform mixture as set forth

in the United States Department of Agriculture Patent Number 3,873,326.

2. Comply with requirements of ASTM C 309 and C 156.

3. Shall be used on pavements subject to receiving large quantities of salt.

Jurisdictional Engineer will determine pavements to receive linseed emulsion.

4. Apply after curing compound has dried.

P. Epoxy Bonding Compound: Iowa

DOT 2301 and I.M. 491.17491.11.

1. Epoxy bonding compound (polymer grouts) shall meet the requirements of

Iowa DOT 2301 and

I.M. 491.17491.11

for each particular application.

2. The material shall be an approved brand as listed in I.M.

491.17491.11.

Q. Concrete Overlays and Whitetopping: Material requirements for concrete overlays and

whitetopping shall be as described for standard PCC paving except as modified below:

1. Bonded Overlays

a. Aggregate:

1) Coarse aggregate type (crushed limestone or gravel) shall be same

as the existing pavement as indicated in the contract documents.

2) Coarse aggregate shall meet Iowa DOT 4115,

Gradation No. 5

3) The largest particle size of the coarse aggregate shall be less than or equal to

one-third of the overlay thickness.

b. Concrete Mix: C-3WR mixture, with or without flyash.

c. For projects with mainline paving greater than 50,000 square yards, a QM-C design

mixture as described in Iowa DOT 2310 shall be

used.

2. Unbonded Overlays: HMA Stress Relief Course

a. Asphalt Binder: PG 58-28

b. Mixture: 300,000 ESAL, 3/8 inch mix, per Iowa

DOT 2303.

1) No maximum film thickness restriction

2) No minimum filler/bitumen ratio restriction

c. Aggregate:

1) Type B

2) No percent crushed particle requirement

3) Gradation shall fall below the restricted zone.

2.03 MIXES: IOWA DOT IM 529

A. Mix Design: Unless otherwise specified, the mix design shall be Class C or C-V47B

mix with air entraining. If a different mix is specified in the contract documents or if the

Contractor requests a mix different than C or C-V47B, the Contractor shall submit to the

Jurisdictional Engineer the paving mix design for approval two weeks prior to starting paving

operations. The submittal shall contain the mix number as described below and admixtures in

accordance with Section 7010, 2.03E. Unless otherwise specified, the minimum

compressive strength of the mix shall be 4,000 pounds per square inch at 28 days.

B. Mix Number: Mix numbers designate numerous aspects of the particular mix. The

following is an explanation of the various aspects of the mix number. For example: C-4WR-C10.

1. The first letter designates the class of concrete as designated in the contract

documents.

2. The number indicates the relationship of coarse aggregate to fine aggregate. A mix

with a 4 is a 50/50 mix. The following chart shows the number within the mix number and

the proportions of the aggregates for each number:

2 is composed of 40% fine and 60% coarse.

3 is composed of 45% fine and 55% coarse.

4 is composed of 50% fine and 50% coarse.

5 is composed of 55% fine and 45% coarse.

6 is composed of 60% fine and 40% coarse.

7 is composed of 65% fine and 35% coarse.

8 is composed of 70% fine and 30% coarse.

3. The letters WR indicate water reducer is used in this mixture.

4. When a C or an F is shown toward the end of the mix number, fly ash is a part of

the mixture and C-fly ash or F-fly ash, respectively, is used. The percentage of fly ash

being used in the mixture shall be designated at the end of the mix number.

5. In certain mix designations, the letter V appears after the first hyphen. This

indicates that a Class V aggregate is to be used. If no letter is shown, aggregate

other than Class V shall be used.

C. Concrete Mixes: Shall meet the following design targets, as per

Iowa DOT 2301,

IM 529.

| |

|

|

Basic Absolute

Volumes of Materials for Unit Volume of Concrete |

| Mix |

W/C Basic |

W/C Max. |

Cement Min. |

Water |

Entrained Air |

Fine Aggregate |

Course Aggregate |

| A-4(1) |

0.474 |

0.532 |

0.108 |

0.161 |

0.060 |

0.335 |

0.336 |

| B-4(2) |

0.536 |

0.600 |

0.093 |

0.157 |

0.060 |

0.345 |

0.345 |

| C-3WR |

0.430 |

0.489 |

0.108 |

0.146 |

0.060 |

0.309 |

0.377 |

| C-4 |

0.430 |

0.488 |

0.118 |

0.159 |

0.060 |

0.331 |

0.332 |

| C-4WR |

0.430 |

0.489 |

0.112 |

0.151 |

0.060 |

0.339 |

0.338 |

| M-4 |

0.328 |

---- |

0.156 |

0.161 |

0.060 |

0.312 |

0.311 |

| O-4WR |

0.327 |

----- |

0.156 |

0.160 |

0.060 |

0.312 |

0.312 |

| (1) Concrete Base, temporary

pavement, or recreation trails only. |

| (2) Temporary or recreation

trails only. |

| Other approved mixes will follow

Iowa DOT IM 529. |

| |

Basic Absolute Volumes of

Materials for Unit Volume of Concrete |

| |

W/C Basic |

W/C Max. |

Cement Min. |

Water |

Entrained Air |

Class V. |

Limestone |

| C-V47B |

0.440 |

0.560 |

0.107 |

0.148 |

0.060 |

0.479 |

0.206 |

| M-V |

0.390 |

---- |

0.160 |

0.196 |

0.060 |

0.555 |

0.029 |

The above mixtures are based on Type I cements (Sp. G. = 3.14). Mixes using blended

cements (Type IP, I(PM), IS, or I(SM)) must be adjusted for specific gravities listed

in Iowa DOT IM 401.

D. Consistency and Workability: The amount of materials

used shall produce a concrete of uniform consistency, workability and a satisfactory

surface finish.

| Paving |

Type of Concrete |

Slump-in |

% Air Content of Fresh

Unconsolidated Concrete

(Before Paver) |

Target % Air,

Consolidated

Concrete

(After Paver) |

| Min. |

Max. |

Target

or

Initial* |

Acceptable

Range |

| Minus |

Plus |

| Machine Finish |

A, B, C, C-V47B |

½ |

2½ |

7.5 |

1 |

1 ½ |

6 |

| Hand Finish |

A, B, C, C-V47B |

½ |

4 |

7 |

1 |

1 ½ |

6 |

| Curb & Gutter |

C, C-V47B |

---- |

3 |

7 |

1 |

1 |

6 |

| Base (Machine Finish) |

A |

½ |

2½ |

7 |

1 |

1 ½ |

6 |

| Base (Hand Finish) |

A |

½ |

4 |

7 |

1 |

1 ½ |

6 |

| Patches with CaCl |

M, M-V |

1 |

3 |

5** |

2 |

2 |

N/A |

| Patch w/o CaCl |

M, M-V |

1 |

3 |

6 ½ |

1 ½ |

1 ½ |

N/A |

As per Iowa DOT 2301, 2511,

2512, 2529, and

2530.

* The initial values for fresh concrete listed in the table above account for anticipated air

loss during consolidation of concrete during placement and paving. Actual air loss and target value

for air content of fresh concrete are established below.

** Prior to addition of Calcium Chloride

E. Air Content for Mainline Paving:

1. Establishing the Target Air Content

a. On the first day of paving, the air content of fresh, unconsolidated concrete shall

be in accordance with the table above for Initial Air Content.

b. The air content of concrete before and after consolidation (in front of and behind

the paver), shall be tested within the first 10 loads. The air content behind the paver

shall be checked at two locations. Samples behind the paver shall be taken such that they

are representative of the entire cross section (one sample from each side of the slab) and

the results averaged.

c. The target air content for fresh, unconsolidated concrete for a specific concrete

mixture and paver shall be established based on the initial samples taken. The air loss

due to consolidation (the difference in air content before and after the paver) shall be

added to the target value for finished concrete and rounded to the next higher 0.5% to

establish the target air content for fresh, unconsolidated concrete.

2. Minimum Testing Frequency

a. The air content of fresh, unconsolidated concrete (in front of the paver) shall be

tested every 200 CY.

b. The target air content for fresh, unconsolidated concrete shall be reestablished

whenever the concrete material sources, concrete mix, and/or paver are changed

3. Adjustments

a. The air content of the fresh, unconsolidated concrete shall be maintained at the

established target air content within the range allowed by Section 7010,

2.03D.

b. A new target air content for fresh concrete shall be established, and the mix adjusted

as required, if the loss through the paver changes by more than 0.5% from the previously

established air loss.

F. Use of Fly Ash: The Contractor shall notify the Engineer prior to making concrete mixture

changes which have been approved. Mix proportions for the various mixes using fly ash are included in

the Iowa DOT Materials IM 529.

The following fly ash substitution rates shall replace those given in

Iowa DOT 2301 and as referenced in Iowa DOT IM 529:

Fly Ash Substitution Rates

| Time Period |

Cement Type |

Fly Ash Substitution Rate

by Weight |

March 16 through

September 14 ***

March 16 through

September 14 *** |

Type I and Type II

Type IP and

Type I(PM) |

Not more than 20 percent

Not more than 5 percent * |

September 15 through

October 15

September 15 through

October 15 |

Type I and Type II

Type IP and

Type I(PM) |

Not more than 15 percent

None |

October 16 thru March 15

October 16 thru March 15 |

Type I, Type II, & Type III

Type IP and Type I(PM) ** |

None

None |

| March 16 thru October 15 |

Type I, Type II, or Type III

used in Class M mixtures |

Class C fly ash only at not

more than 10 percent |

| * Note: If the cement manufacturer

provides the Jurisdictional Engineer with satisfactory concrete strength and freeze-thaw

durability test results equivalent to concrete with the same Type IP or Type I(PM) cement

without fly ash, the substitution rate may be increased to 10 percent. The testing and

acceptance criteria shall be in accordance with Materials

IM 401. |

| ** Note: Proportions of Type IP and

Type I(PM) shall be increased 15 percent, by weight, during this time period. |

| *** Note: The March 16 through

September 14 substitution rate may be used at any time the maturity method for monitoring

concrete strength is utilized. |

Fly ash shall be transported, stored, hauled, and batched in such a manner to keep it dry.

2.04 MIXING EQUIPMENT

A. Weighing and Proportioning Equipment: Iowa DOT

2001.

B. Mixing Equipment: Iowa DOT 2001.

C. Material Bins: Iowa DOT 2001.

2.05 CONCRETE BATCHING: IOWA DOT 2301

A. Plant batching shall be Iowa DOT calibrated and approved. Provide copy of current calibrations

and approvals.

B. Batch plant operation and batch trucks shall be coordinated with the paving operation in order

to ensure a steady supply of materials.

C. Batch plant and trucks shall be operated to minimize dust, noise or truck nuisances.

2.06 CONCRETE MIXING

A. Construction or Stationary Mixer: Iowa DOT

2301.

1. The concrete shall be uniform in composition and consistency. If this condition is not

produced because of the size of the batch, the size of the batch may be reduced or the mixing

time increased, or both, until this result is obtained. If non-uniform, concrete producers

shall take corrective action.

2. Concrete transported without continuous agitation shall not be used if the period elapsed

between the time the concrete is mixed and the time it is placed is greater than 30 minutes. The

mixed-to-placed time period may be extended an additional 30 minutes with the use of a retarding

admixture, upon approval of Jurisdictional Engineer.

3. Concrete transported with agitation shall not be used when the time between start of mixing

and placement is more than 90 minutes.

4. The methods of delivering and handling the concrete shall be such that objectionable

segregation or damage to the concrete will not occur, and that which will facilitate placing

with a minimum of handling.

5. The compartment in which concrete is transported to the work shall be thoroughly cleaned

and flushed with water at such intervals as may be necessary to insure that hardened concrete

will not accumulate in the compartment. Flushing water shall be discharged from the compartment

before it is charged with the next batch.

B. Ready Mixed Concrete: Iowa DOT 2301.

1. The concrete shall be uniform in composition and consistency. If non-uniform, concrete

producers shall take corrective action.

2. Proportioned in a central plant and mixed in a stationary mixer for transportation in

trucks without agitation.

3. Proportioned at a central plant, and only partially mixed in a stationary mixer for

transportation and finish mixing in a transit mixer.

4. Proportioned at a central plant, and then mixed in a transit mixer prior to or during

transit.

5. When necessary to add additional mixing water at the site of placement, the batch shall

be mixed at least an additional 30 revolutions of the drum at mixing speed.

6. For main portions of the work it must be demonstrated before the work starts that each

vehicle in which concrete will be delivered is capable of discharging concrete having a slump

not over 2 inches at an overall rate for its entire load of not less than 1.25 cubic yards per

minute. The concrete shall be delivered at a rate sufficient to maintain a sustained rate of

progress of not less than 100 feet per hour for the width and depth of slab to be placed.

7. Concrete transported without continuous agitation shall not be used if the period elapsed

between the time the concrete is mixed and the time it is placed is greater than 30 minutes.

The mixed-to-placed time period may be extended an additional 30 minutes with the use of a

retarding admixture upon approval of the Jurisdictional Engineer.

8. Concrete transported with agitation shall not be used when the time between start of

mixing and placement is more than 90 minutes. However with the approval of the Jurisdictional

Engineer, an approved retarding admixture may be used at the rate prescribed in Materials

IM 403.

9. The compartment in which concrete is transported to the work shall be thoroughly

cleaned and flushed with water at such intervals as may be necessary to insure that hardened

concrete will not accumulate in thecompartment. Flushing water shall be discharged from

the compartment before it is charged with the next batch:

a. Concrete with Type III cement and transported without agitation shall be delivered

and placed within 30 minutes after mixing.

b. With the approval of the Jurisdictional Engineer, an approved retarding admixture

may be used at the rate prescribed in Materials IM

403 and the mixed-to-placed time may be extended by an additional 30 minutes.

C. All Methods: Each truck load shall be identified by a plant charge ticket showing

plant name, contractor, project data, quantity, class, time batched, and water added at site.

2.07 CONCRETE PLACEMENT EQUIPMENT: IOWA

DOT 2301

A. Subgrade Finishing Equipment: Use mechanical excavating equipment designed for this

purpose, approved by Jurisdictional Engineer.

1. Form line or path area for slip-form paving machine shall be constructed to final

grade by form-line excavating equipment with automatic grade controls.

2. Subgrade between forms or between path areas for slip-form machines constructed to

final grade with automatically controlled subgrade excavating machine.

B. Side Forms: Steel, minimum thickness: 5 gage, height at least equal to design

thickness of pavement with base width at least 6 inches.

1. Minimum section length: 10 feet, joint connections designed to permit horizontal

and vertical adjustment with locking device to hold abutting sections firmly in alignment.

2. Bracing, support, and staking must prevent deflection or movement of forms.

C. Flexible Forms: Use steel or wood flexible forms for curves with radius less than

100 feet.

1. Bracing, support, and staking must prevent deflection or movement of forms.

2. Forms used to form back of curbs at returns shall have height at least equal to design

thickness of pavement and curb height.

3. Forms must be free from scale and surface irregularities; coat with release agent (see

Section 7010, 3.03.G) prior to concrete placement.

D. Consolidating and Finishing Equipment: Fixed form or slip form paving machines

specifically designed for placing, striking off, consolidating, and finishing in single pass to

required cross section.

1. Consolidation of concrete by single pass of approved surface, tube, or internal vibrator

operated in accordance with manufacturer's recommendations.

2. Slip form equipment: Automatic horizontal and vertical controls required; equipment

must spread concrete to uniform depth prior to finishing.

3. Air screeds and vibrating screeds are approved consolidating and finishing equipment

for cul-de-sacs, drives and some intersections. Small runs of pavement up to 250 feet maximum

may also require screeds if paving machines are not practical.

4. Equipment subject to approval of Jurisdictional Engineer.

E. Hand Finishing Equipment: Contractor shall provide tools including wood or magnesium

floats, wood hand floats, point trowels, edgers, or other equipment necessary for proper finishing

of concrete.

1. Provide 2 light straightedges, 10 feet long, with handles not less than 12 feet long for

use in detecting irregularities in surface; provide 2 heavy straightedges of similar size for

use in correcting surface; provide 2 light straightedges 10 feet long for checking curb and

gutter line.

2. Provide approved vibrators for consolidating concrete.

3. Provide metal or wood screed true to crown.

F. Curing Equipment: Use pressure sprayer capable of applying a continuous uniform film

of curing compound.

G. Concrete Saws: Power operated concrete saws capable of cutting hardened concrete neatly.

H. Joint Sealing Equipment: Equipment capable of heating and installing sealant in joints

in accordance with manufacturer's recommendations.

2.08 Surface Preparation and Cleaning Equipment:

A. Cold Milling machine capable of scarifying existing surface to the depth required

B. Shot blasting machine capable of removing rust, oil, and concrete laitance from existing

surface.

C. Sand blasting equipment capable of removing rust, oil, and concrete laitance from the

existing surface.

3.01 FINAL SUBGRADE/SUBBASE PREPARATION

A. Natural Subgrade:

1. Subgrade construction shall meet the requirements of Section

2010, Part 3.

2. Should the subgrade be left high or not prepared for final template shape by a previous

contractor, the subgrade shall be proof rolled and depressions filled in accordance with

Section 2010.

3. Trimming:

a. If the subgrade is to be trimmed to the final grade elevation with an

automatically controlled trimming machine, the prepared subgrade shall be graded

to an elevation that will permit the machine to accomplish the final cut in one

continuous forward pass.

b. In irregular or short sections, the subgrade shall be checked by the most

accurate practical method, subject to approval of the Jurisdictional Engineer.

4. Unless otherwise ordered by the Jurisdictional Engineer, the subgrade, at time of

placing concrete for Concrete Pavement, shall be in a uniformly moist but not muddy condition

to a depth of not less than one inch.

5. Subgrade Loading:

a. Where concrete trucks must travel on a prepared soil-type subgrade to unload

and, as approved by the Jurisdictional Engineer, watering of the subgrade must be

limited to just ahead of the paving machine.

b. Repetitive loading on the subgrade by concrete trucks shall be minimized by

entering and exiting the subgrade on side streets.

c. Loads in excess of the legal axle load shall not be allowed on the completed

subgrade.

d. Partially loaded trucks may be required.

e. If subgrade/subbase failure occurs, the repair shall be coordinated with the

Jurisdictional Engineer.

6. Paving Suspended:

a. The paving operation shall be suspended where subgrade stability has been lost.

b. No concrete shall be placed upon a subgrade which has become unstable, bears

ruts or tire marks of Contractor's equipment or which is excessively softened by

rain until such subgrade has been reconsolidated and replaned or reshaped to correct

the objectionable condition.

c. If necessary, scarify to a minimum depth of 6 inches, aerating, and recompacting

at the Contractor's expense. Recompaction shall meet requirements of

Section 2010, 3.07.

7. Maintenance of Subgrade:

a. The Contractor is responsible for maintenance of the completed subgrade during

subsequent construction activities.

b. Before allowing hauling equipment to use the completed subgrade, the Contractor

must be satisfied as to the effect this hauling equipment may have on the partially

completed work.

B. Granular Subbase:

1. Granular Class A, B, C, and D subbase construction shall meet the requirements of

Section 2010, 2.04 D and Section

2010, 3.09.

2. Should the Contractor who constructed the subbase elect to overbuild the subbase,

the paving contractor shall trim down to the design elevation and shape to the final

template with an automatically controlled trimming machine.

3. Excess material shall be salvaged and spread for use on any other approved project

location or operation.

4. The top 1 inch of the subbase shall be uniformly moist prior to paving.

5. Construction traffic may be allowed only on Class A subbase (special backfill),

Class C subbase (RAP special backfill), and Class D subbase (modified) upon approval

of Jurisdictional Engineer. (See Section 2010, 3.09, E, 4)

6. The paving operation shall be suspended where subbase stability has been lost.

3.02 SURFACE FIXTURE ADJUSTMENT

A. Adjust manhole frames and other fixtures within area to be paved to conform to

finished surface.

B. Clean outside of fixture to depth of pavement before concrete placement.

C. Box out fixtures for later adjustment where allowed. Size and shape of box out

for intakes as shown in Standard Drawings.

3.03 FORMS SETTING

A. Use form line excavating machine to establish subgrade of forms.

B. Set base of forms at or below subgrade elevation with top of forms at pavement

surface elevation.

C. Extra height forms with Jurisdictional Engineer approval may be used to back

up integral curb and paving slab; set base at or below subgrade elevation with top

of form at top of curb elevation.

D. Secure forms in place to required grade and alignment.

E. If voids occur under forms, remove forms and rework subgrade to proper elevation

and density; reinstall forms.

F. If the soil supporting the form is softened by rain or standing water so that

form is inadequately supported, remove forms and rework subgrade to proper elevation and

density; reinstall forms.

G. Coat forms with release agent before concrete is placed.

H. Place forms true to alignment and free of latent concrete.

3.04 REINFORCING PLACEMENT

A. Reinforcing metal shall be clean, straight, free from distortion and rust, and shall

be firmly secured in position as detailed.

B. All reinforcing metal shall be placed in approved storage to prevent damage; do not

distribute along the work site except as needed to avoid delay in paving.

C. Place reinforcing steel as shown on the detailed drawings or as specified; support

and secure bars by approved chair and wire assemblies; bars to be checked by the

Jurisdictional Engineer upon notification from the Contractor.

D. Place steel centered in the pavement reasonably in advance of the paving operations.

E. Joint Steel:

1. All joints shall be constructed of the type, dimensions, and at the locations

required by the plans or special provisions.

2. Tie bars for all longitudinal joints shall be installed so as to be in the

intended position in the completed pavement. Tie bars for all longitudinal joints

shall be positioned on chairs and secured against movement with metal stakes during

placing and finishing of concrete unless otherwise approved by the Jurisdictional

Engineer. If approved by the Jurisdictional Engineer, bars may be placed in position

by a machine or other method. For tie steel that is placed mechanically in plastic

concrete, the Jurisdictional Engineer shall:

a. Manually check locations and depth of the steel in the plastic concrete

behind the slip form paver using the following frequencies:

- once every 200 lineal feet for tangent roadway sections

- in at least three locations within all horizontal curve sections

- for each inspection, at least two tie steel locations within a panel

b. Using a magnetic locator, verify locations of tie steel in hardened concrete

every day. Check out-of-tolerance tie steel to identify the extent of the problem

for a retrofit correction.

3. The Contractor shall provide adequate means to ensure that the load transfer

devices and tie bars for key type joints are properly secured to maintain correct

position and alignment during the placement of concrete.

4. Other tie bars shall be placed in such a manner as to ensure that the bars are

located in reasonably close conformity with the specifications.

5. Care should be taken to prevent disturbance or damage of the joint assembly.

Bars must be supported by approved chairs or method approved by Jurisdictional Engineer.

F. Dowel Holes:

1. Holes for both deformed and smooth dowel bars shall be drilled into the face of

the existing slab at midpoint.

2. Drills used to make holes shall be held in a rigid frame to assure proper

horizontal alignment with misalignment not to exceed 1/4 inch in the vertical or

horizontal plane.

3. The equipment used shall be operated so as to prevent damage to the pavement

being drilled. The drilling procedure shall be approved by the Jurisdictional Engineer.

The hole shall be blown clean to eliminate all dust.

4. Dowels shall be epoxied into place in the existing slab. Epoxy bonding compound

shall meet requirements of Section 7010, 2.02 P.

G. Bar Mats:

1. When bar mat assemblies are specified, the reinforcement shall be assembled

accordingly and firmly fastened together at all bar intersections.

2. Mat assemblies shall be placed, secured, latched and tied for a continuous mat

at adjacent ends as detailed on the plans. Displacement during concrete placement

operations shall not be permitted.

3. Mat assemblies shall not be placed without the use of chairs to assure proper

positioning; maintain to proper clearances.

H. Steel Fabric: When fabric is specified, it shall be placed in sheets at the

depth shown on the plans.

3.05 CONSTRUCTION OF JOINTS (See

Figures 7010.1 A through 7010.4 C)

A. General:

1. Longitudinal and transverse joints shall be constructed of the type, dimensions,

and at the locations required, as described by these specifications, or as detailed

by the plans or special provisions.

2. Longitudinal joints shall be coincident with or parallel to the pavement center

line unless shown otherwise on the plans.

3. All transverse joints shall be at right angles to the center line and shall

extend the full width of the pavement unless otherwise specified.

4. All joints shall be perpendicular to the finished grade of the pavement and

the alignment across the joint shall not vary from a straight line by more than 1

inch.

5. All joint fillers shall be installed as shown in the contract documents.

6. The Contractor shall exercise care in placing, consolidating, and finishing

the concrete at and about all joints.

7. The edges of the pavement at tooled joints shall be rounded, where required,

as specified on the standard detailed plates.

8. Wet sawing shall be used when required by the contract documents for dust control.

B. Expansion Joint:

1. Install expansion joints where shown on plans and as shown on Standard Drawings.

2. Prevent movement of or damage to joint assembly when placing concrete; set joint

material low enough to clear the finish machine.

3. Construct double width expansion joint in curb over expansion joint in pavement.

The backside of the joint must be clear of concrete.

4. The expansion joint shall be aligned straight and true.

5. If joint fillers are assembled in sections, or if joints as a whole are constructed

in sections, then no offsets shall be between adjacent units.

6. Where more than one section is used in a joint, the sections shall be securely

laced or clipped together. Damaged basket assemblies shall not be used.

C. Saw Joints:

1. Joint locations shall be chalked with a string line before sawing.

2. Joint dimensions:

a. All transverse contraction joints shall be sawed at a maximum spacing of 21T,

where T is the thickness of the pavement in feet.

b. All joints shall be sawed to a depth shown below and on the detail plate.

| |

Minimum Sawcut Depth |

| |

Conventional Saw |

Early "Green" Saw |

| Transverse "C" Joint |

T/3 |

1 ¼" |

| All other Transverse Contraction joints |

T/3 |

1 ¼" |